The printing accuracy can reach the nanometer level, and the diameter of the nanofibers can be adjusted and controlled;

Melt electrospinning and solution electrospinning capabilities;

Precise temperature control to solve the problem of yellowing of materials for long-term printing;

Unique software algorithm that supports patterned custom printing;

The flat or tubular scaffold can be prepared with adjustable tube diameter, which can be used for cell culture or vascular scaffold;

- Two different printing methods of solution near-field direct writing and melt near-field direct writing can be realized on the equipment, and the solution nozzle or melt nozzle can be manually replaced according to actual needs;

- Near-field solution direct writing can prepare nanofibers with a diameter of 50nm-20μm, and near-field melt direct writing can prepare nanofibers with a diameter of 500nm-50μm;

- Melt direct writing does not require the use of solvents, no solvent residues, environmental protection, and high efficiency;

- Highly oriented nanofibers can be prepared by near-field direct writing electrospinning technology, andcomposite nanofiber materials with 2D or 3D structures can be printed;

- With exclusive patented technology, the printing accuracy can reach nanometer level, which is a powerful tool for micro-nano manufacturing.

- The printing accuracy can reach the nanometer level, and the diameter of the nanofibers can be adjusted and controlled, which can meet the needs of different researchers.

- Melt near-field direct writing and solution near-field direct writing dual-function modules to achieve flexible configuration.

- Precise temperature control to solve the problem of yellowing of materials for long-term printing.

- Automatic calibration function, saving research time.

- The original software algorithm can design different arrangements of fibers, and the path can be controlled by modifying parameters.

- Support custom pattern printing, line and curve printing.

- Equipped with a high-definition camera to capture the printing process and details.

- The flat or tubular scaffold can be prepared with adjustable tube diameter, which can be used for cell culture or vascular scaffold.

- Near-field direct writing electrospinning machine can prepare biological tissue engineering scaffolds of ordered nanofibers to guide and stimulate the growth of bone, muscle, nerve tissue, etc.

- 2D or 3D electrospinning nanofiber composites have broad application prospects. In biomedicine, it can be used as drug control, wound dressing, biosensors. In terms of advanced fabrics, biodegradable textiles can be printed, and can also be used as catalysts in new energy batteries, electronic information technology, and microfluidic chips.

Item | Parameters and configuration | |

High voltage power supply

| -Output voltage DC: 0 ~ -30KV, current <1mA. | |

Nozzle system | Melt nozzle | - Heating temperature from room temperature to 300°C; - Pneumatic feeding, the minimum air pressure of the high-precision pressure regulating valve can be adjusted by 0.01Mpa. |

Solution nozzle | -Single needle nozzle, 13-34G needle can be replaced at will; -Applicable syringe specifications: maximum 10ml; - Liquid supply speed: minimum 10ul/h. | |

Note: The above two nozzles need to be switched manually | ||

X-Y-Z three-axis mobile platform | - The effective stroke of the Z-axis is 80mm; - It is used for the height adjustment of the nozzle, and the adjustment range is 0~80mm; - The motion accuracy: 5μm. | |

- Effective stroke of X, Y-axis: 200mm×200mm; - Collection speed: 0~300mm/s; - Square wave trajectory collection and custom trajectory collection; - Movement accuracy ≤ 2μm. | ||

Collection platform | - Conductive glass collection; - Effective collection area: 100mm×100mm. | |

Environmental Control System | - Environmental temperature control: room temperature~50℃. | |

Camera system | - High-definition microscope camera; - Resolution: 1080P; - The magnification is adjustable from 50X to 500X. | |

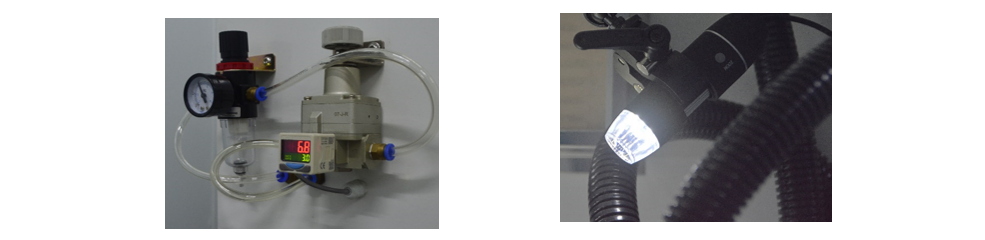

Gas source | - Oil-free and water-free air source; - The highest pressure is 0.8Mpa; - The maximum flow rate is 40L/min. | |

Control System | - PC man-machine control interface; - Control parameter setting (manual speed setting, automatic motion speed setting, height adjustment setting, return to zero point, and related control buttons); - Real-time parameter monitoring; - Parameter record; - Customize track settings. | |

Cable | - 220v power cord, 2 triangle plugs; - Communication line, one 64-pin; - Communication extension cable, one 64-pin. | |

Consumables | Specifications |

Exhaust pipe | φ80mm×2M |

Melt direct writing debugging materials | PCL 20g |

Solution Direct Write Debug Solution | 5% PEO solution 20ml |

Stainless steel syringe | 10CC |

Musashi needle (separate type) 25G | Diameter of 0.25 mm |

Musashi needle (separate type) 30G | Diameter of 0.3 mm |

Conductive glass | 150×150mm |

50×50mm | |

Repair tool Allen wrench | standard |

Stainless steel base | / |

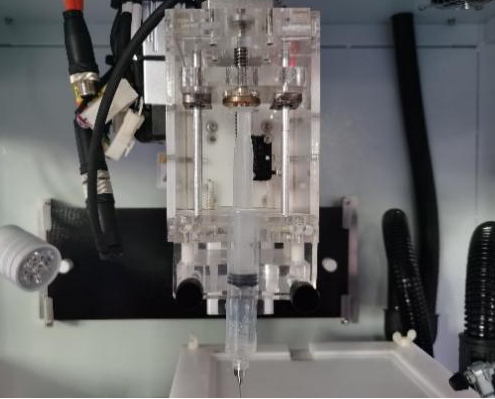

Melt nozzle

-Special high-temperature heating head for biological materials, the heating temperature can reach room temperature 300℃;

-Pneumatic feeding, the minimum air pressure of the high-precision pressure regulating valve can be adjusted by 0.01Mpa;

-The barrel is easy to clean, and the stainless steel barrel can be used repeatedly.

The picture on the right shows the melt nozzle |

|

|

Solution nozzle

- Applicable to a wide range of nozzle diameters, 13-34G needles can be replaced at will;

- Applicable medical-grade syringe specifications: maximum 10ml;

- High-precision liquid supply system, the minimum liquid supply volume is 10ul/h.

The picture on the right shows the solution nozzle |  |

|

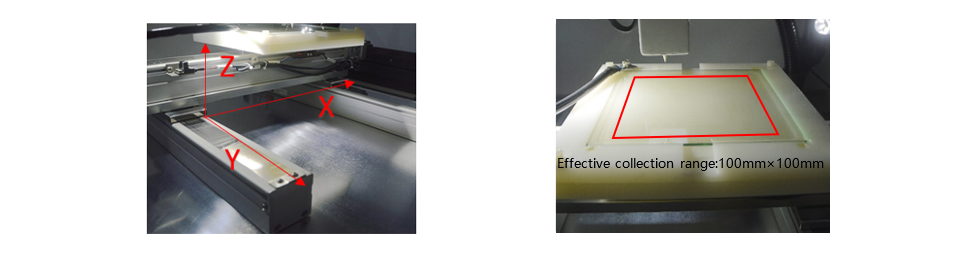

3D motion platform

- The X-axis and Y-axis moving platforms are installed in the middle of the spinning chamber.

- The Z-axis is installed vertically on the top of the spinning chamber to adjust the height of the nozzle.

- The collection platform conductive glass is installed on the X-Y axis moving platform.

- Effective collection range: 100mm×100mm.

Working environment

- Ambient temperature can be controlled at room temperature ~ 50 ℃;

-With a high-definition microscope camera system, it is convenient to observe the spinning process;

- Oil-free and water-free air source, the maximum pressure is 0.8Mpa, and the maximum flow rate is 40L/min.

After-sales service

-Under normal circumstances, the free warranty period of the whole machine will be paid for maintenance for life within one year after arriving at the customer's site.

-If the unnatural damage caused by improper use or modification by the user is not covered by the above warranty, the user must pay the repair cost.

Environmental requirements

Ambient temperature: 10℃~40℃.

Relative humidity: 10%~60%.

Compressed air requirements (if any).

Compressed air pressure: 0.5~0.7Mpa.

Compressed air outlet pipe diameter: 1 inch.

Dew point -40℃, solid particle size ≤0.1um.

The oil content is ≤0.01mg/m³.

Party A accesses the designated location as required by Party B.

Electricity requirements

-The power supply of all manufactured electrical and electronic equipment adopts 50Hz (±1), 220V/380 (±10%) three-phase AC voltage to ensure the first-level grounding of the power supply (three-phase five-wire system).

Foundation requirements (if any).

The foundation ground is compacted to ensure 1000Kg/m2, and the ground level difference is ±3mm. (It is recommended that the concrete grade is above C30).

There is no strong vibration interference, no corrosive medium, no strong electromagnetic radiation, etc. around.

Safety: Comply with national equipment safety regulations.