Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

About Us

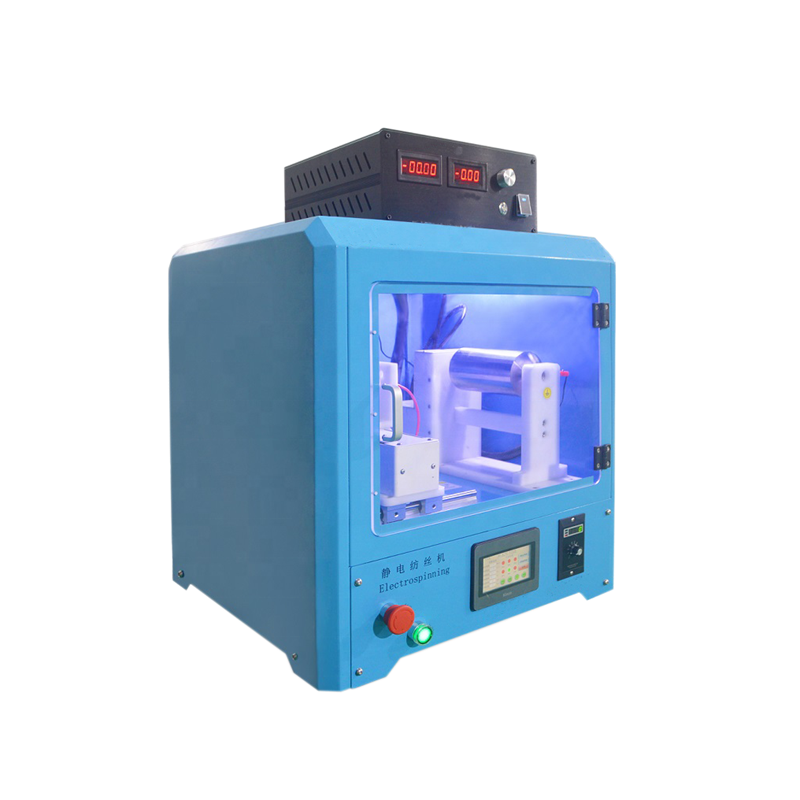

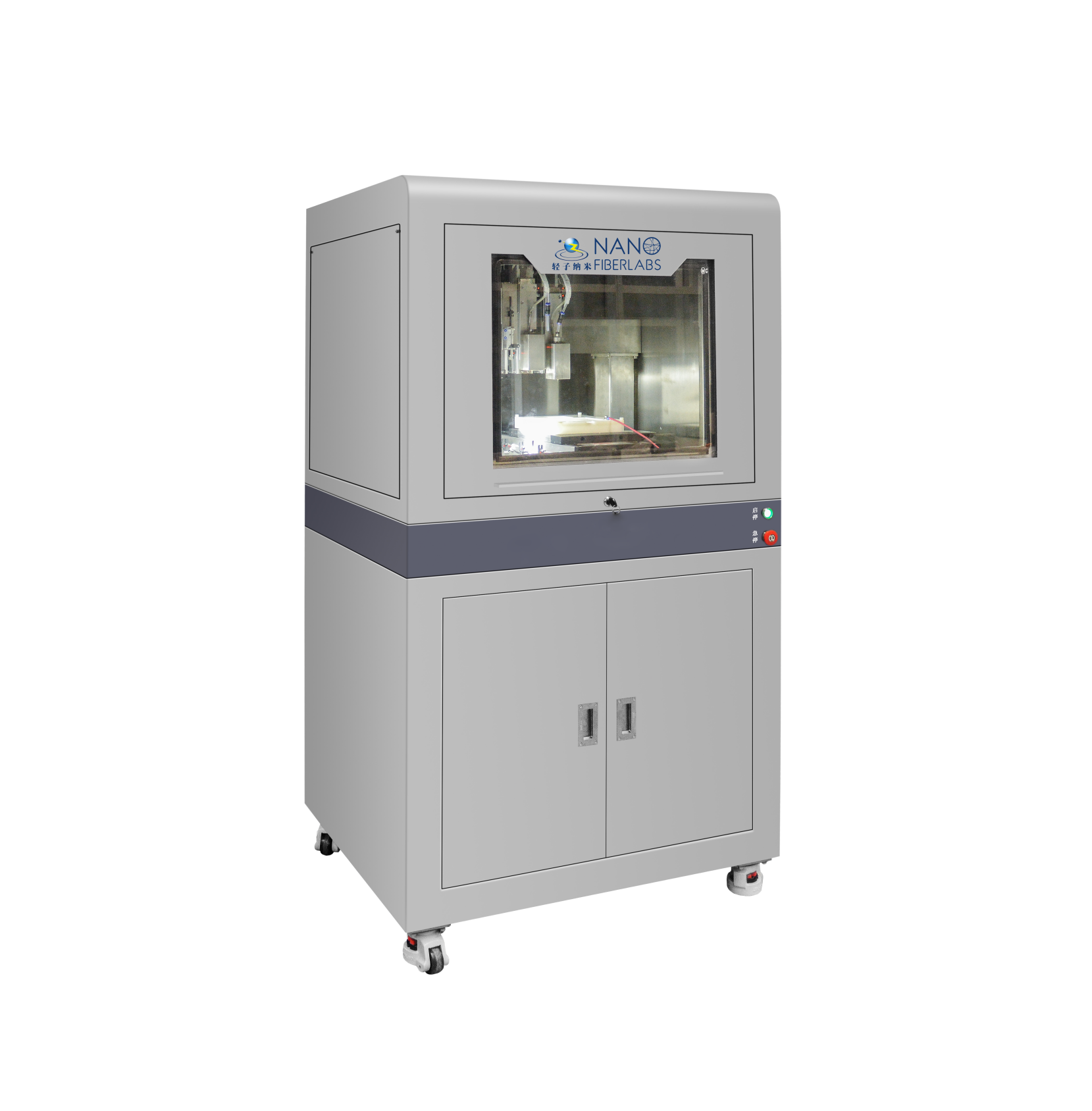

The R&D team of Foshan MBRT Nanofiberlabs Technology Co., Ltd. was established in 2002. The company's machine products include: Electrospinning machine, Flash Joule Heating machine(FJH), nano dry ice snow cleaning machine, EHD printing machine, etc. Nanofiber new material products include: Air filter media, windproof waterproof and breathable fabrics for clothing, instant nanofiber membranes for beauty, waterproof and breathable membranes for medical treatment. Our R&D team holds over 200 patents, cooperates with more than 10,000 cooperative clients, and has engaged in over 100 industrial cooperation cases worldwide. The company is dedicated to technological innovation and customer service, strives to create more valuable products and provide excellent service. We warmly welcome friends from around the world to negotiate and cooperate with us.

authorized invention patents

utility model patents

PHDS

Masters

![[Hot Announcement] The 2nd International Conference of Advanced Medical Engineering (I-CAME2025) is Coming Soon!Foshan Wemaxnano Technology Invites You to Join Us in Shanghai!](https://nanofiberlabs.usa18.wondercdn.com/uploads/image/685a3f06483f9.png)