Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

1. Wound dressing

Wound dressings are a basic type of medical device used to cover open wounds to protect them from external risk factors. Novel multifunctional wound dressing simultaneously provides the right microenvironment to support the wound healing process. Electrospun nanofiber materials are characterized by high porosity, high air permeability, and moisture permeability. And it is considered to be an advanced dressing candidate material with prospects for wound healing and skin regeneration due to its effective barrier properties against external pathogens and good extracellular matrix (ECM) fiber-mimicking properties.

2. A new type of wound dressing---gelatin nanofiber mats

Gelatin is one of the natural biomaterials for electrospinning nanofiber dressings, which has excellent biocompatibility and biodegradability, as well as great exudate absorption capacity. Electrospun gelatin-based nanofiber mats that integrate specific functionalities have been fabricated to treat some difficult-to-heal wound types.

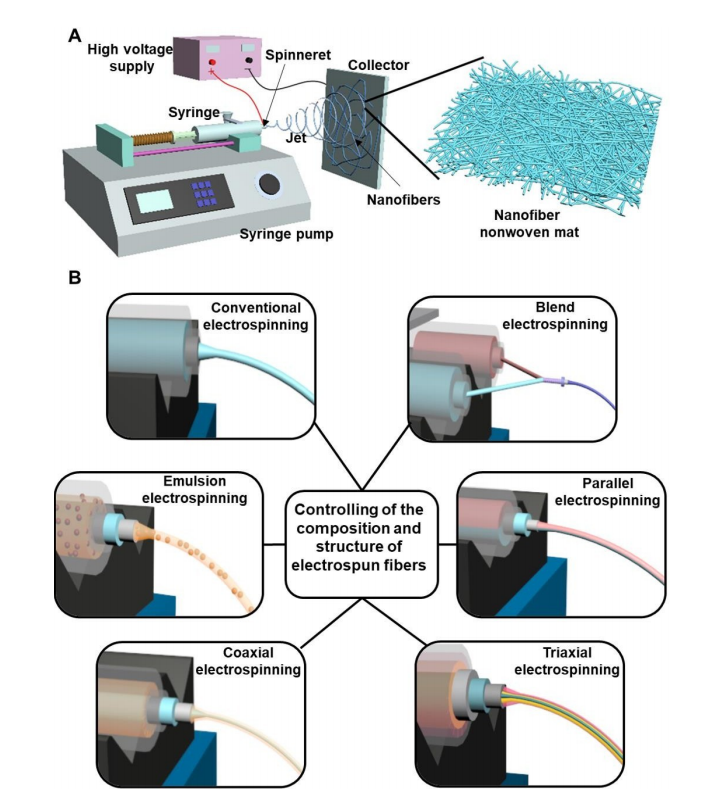

The development of new wound dressing materials has shortened the healing time and improved the function of healing wounds. Electrospinning has been extensively studied as a promising technique for fabricating nanofiber nonwoven mats. It has attracted intense attention in the fields of regenerative medicine and tissue engineerings, such as wound healing, drug delivery, and osteochondral and gastrointestinal tissue engineering.

Although there are many different types of polymers electrospinning into nanofibers, gelatin is undoubtedly one of the most important biopolymers for making electrospinning nanofibrous mats for wound healing applications. At present, scholars have conducted in-depth research on the clinical application of electrospinning gelatin-based dressings.

Figure 1. (A) Schematic diagram of a conventional electrospinning device. (B) Schematic illustration of some representative improved electrospinning strategies for controlling the composition and structure of electrospun fibers

3. Electrospinning gelatin-based nanofiber mats

A team of scholars has produced electrospinning gelatin/hydroxyapatite nanofiber pads as wound dressing materials, which have a higher wound closure percentage than commercial chitosan gel wound dressings. This nanofiber dressing can effectively reduce the invasion of inflammatory cells and significantly promote re-epithelialization.

A research team employed a dual electrospinning strategy to fabricate novel composite dressings containing CS-gelatin (gel) nanofibers and CS-HA nanofibers. In vivo wound treatment results showed significantly higher wound closure with CS-gel nanofiber dressing compared to medical gauze.

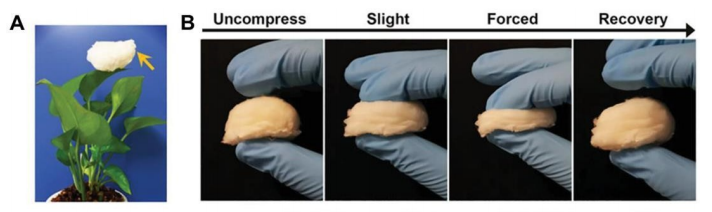

Altering the structure and pattern of electrospun gelatin-based nanofiber dressings is also very important to improve the healing efficiency of the finally obtained dressing materials. Another research team developed a three-dimensional gelatin nanofiber sponge using a combination of improved electrospinning technology and subsequent thermal cross-linking treatment. This material accelerates the generation of platelet plugs and activates the coagulation pathway. Both the in vivo liver trauma model and the ear artery injury model showed that the prepared 3D gelatin nanofibrous sponge had higher hemostatic ability than the commercial 3D gelatin non-fibrous hemostatic sponge and medical gauze. Shows great potential for rapid hemostasis in large-scale acute wounds.

Figure 2. Design and development of a novel 3D electrospun gelatin nanofiber sponge for rapid hemostasis. (A) Photograph of the as-prepared 3D electrospun gelatin nanofiber sponge standing on a leaf. (B) Photographs of compression and recovery of gelatin nanofiber sponges under different degrees of external force.

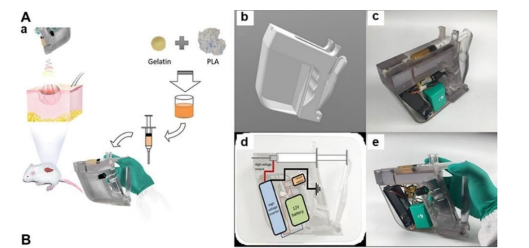

In addition, in situ dressings are particularly suitable for irregularly shaped wounds. Recently, a research team used a 3D printer to create a handheld electrospinning device. The gelatin/PLA nanofiber pads were electrospun at the wound site of mice using the fabricated hand-held electrospinning device to achieve in situ repair of the wound.

Figure 3. Design and development of an in situ gelatin/PLA nanofiber wound dressing using a 3D printed hand-held electrospinning device.

4. Electrospinning gelatin-based nanofibrous mats loaded with bioactive agents

During the electrospinning process, two or more biologically active and therapeutic ingredient agents have been loaded into the gelatin-based nanofiber mat. Ajmal et al. developed PCL/gelatin nanofiber pads loaded with quercetin and ciprofloxacin hydrochloride, which exhibited sustained release after initial rapid release. The drug-loaded PCL/gelatin nanofiber dressing demonstrated good antibacterial and anti-inflammatory effects in vivo and accelerated wound healing.

5. Summary

In the past two decades, scholars have made great efforts in the selection of polymer blends, the selection of solvents and functional additives, and post-processing strategies such as physical or chemical cross-linking. To improve water resistance, control degradation rate, and enhance the physical and biological properties of electrospun gelatin-based nanofiber mats. Combined with electrospinning gelatin-based nanofibers by using some advanced electrospinning methods, such as blend electrospinning, emulsion electrospinning, and coaxial electrospinning. Despite all these advances, there is still no commercialized electrospun gelatin-based nanofiber wound dressing in the clinic.

References: https://www.mdpi.com/2079-4991/12/5/784

Nanofiberlabs, as an electrospinning equipment manufacturer, is committed to taking electrospun materials from the laboratory to actual production. We can provide experimental electrospinning devices and industrial production equipment.