Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Contents

1. Properties of PA material

2. Application of electrospinning PA

3. Process of electrospinning PA

4. Common spinning problems and solutions

1. Properties of PA materials

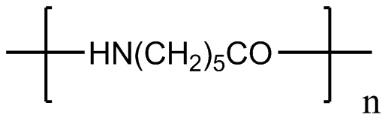

Polyamide (PA) is a polymer formed by the polymerization of monomers containing carboxyl group and amino group through amide bond. It is soluble in formic acid, acetic acid, hexafluoroisopropanol and other solvents. When used as a plastic, polyamide is called nylon, and when used as a synthetic fiber, it is called chinlon. Polyamides can be made from binary amines and diacid, or they can be synthesized from ω-amino acids or cyclolactams. According to the different number of carbon atoms contained in the binary amine and diacid or amino acid, a variety of different polyamides can be prepared. At present, there are dozens of varieties of polyamides, among which PA-6, PA-66 and PA-610 are the most widely used. The joint structures of PA-6, PA-66 and PA-610 are [NH(CH2)5CO], [NH(CH2)6NHCO(CH2)4CO] and [NH(CH2)6NHCO(CH2)8CO], respectively. PA-6 and PA-66 are mainly used for spinning synthetic fibers, known as nylon -6 and nylon -66.PA-610 is a kind of thermoplastic engineering plastics with excellent mechanical properties. PA has good comprehensive properties, including mechanical strength, heat resistance, wear resistance, chemical resistance, electrical insulation and self-lubrication. And it is easy to process with low coefficient of friction, a certain flame retardancy.

Figure 1 Structural formula of polyamide

2. Application of electrospinning PA

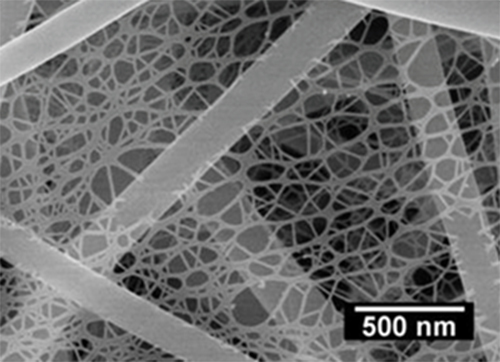

(1) Air/water filtration:Fiber air filtration materials are composed of complex arrays of fibers, the pore size of traditional fiber air filtration materials is comparatively large, Even the pore size of the melt-blown filter material with good filtration performance is also in the range of ten to dozens of microns, and the effect of filtering fine particles is not good. PA has good electrospinning performance. Electrospinning PA nanofibers usually have a diameter of 80-200nm, which is relatively thin among electrospinning materials. In particular, nano-fibers (80-200nm)/nano-cobweb (~20nm) composite nanofibers can be prepared by adding an appropriate amount of inorganic salts to adjust the conductivity of the spinning liquid (Figure 2). This very small fiber diameter gives PA nanofiber membrane a smaller pore size, larger specific surface area and adsorption performance, so that PA nanofiber filter material has a great performance advantage in high fine filtration.

Figure 2 SEM image of PA nano cobweb

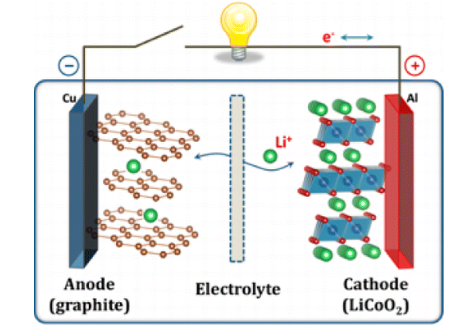

(2) Battery diaphragm

In the structure of lithium-ion battery, the diaphragm is one of the key inner components. The performance of the diaphragm determines the interface structure and internal resistance of the battery, which plays an important role in improving the comprehensive performance of lithium-ion batteries. PA has good thermal stability and mechanical strength, and the amide bond in the molecule has a strong polarity. It also has a strong affinity with high polarity electrolyte. The PA electrospun nanofiber membrane with three-dimensional structure has the advantages of high porosity, uniform pore size distribution, strong structural adjustability, etc. It can be used as a lithium-ion battery membrane with good infiltration and high ionic conductivity, which is expected to improve the charge and discharge capacity, rate performance and cycling performance of the battery.

Figure 3 Schematic diagram of the working principle of lithium-ion battery

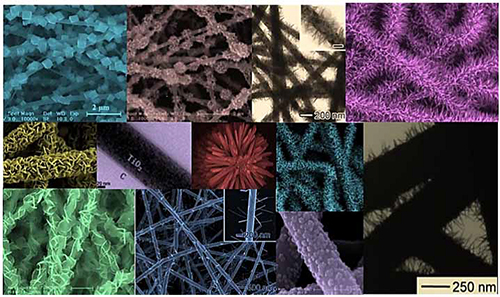

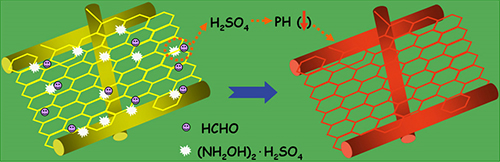

(3) Catalyst support

At present, the research of new nanocatalyst materials is the focus of the field of catalysis. Nanomaterials have important applications in the field of catalysis due to their unique small-size effect, surface effect, quantum size effect, macroscopic quantum tunneling effect, etc. However, nano-catalyst particles are easy to agglomerate, which seriously affects their application scope. Therefore, supported catalyst has become an important research content in the field of catalysis. Electrospinning technology is an important method to prepare one-dimensional nanofiber materials. Electrospinning PA nano-spider web can be used as a carrier to achieve uniform load of nano-catalyst. In addition, the large specific surface area and easy recovery of electrospinning PA nano-spider web can also improve the catalytic activity and recovery performance of the catalyst. Catalyst loading methods include in situ compound method, co-precipitation method, hydrothermal - solvothermal method, etc.

Figure 4 Compositr nanofiber materials prepared by electrospinning combined with hydrothermal(solvolthermal)

(4) High performance sensor material

Electrostatic spinning nanofiber membrane with 3 dimensional hole structure, is advantageous to the target detection objects diffusion quickly inside the fiber membrane. At the same time, PA nano-spider web has a high specific surface area and is easy to functional modification. It can provide abundant active sites for the adsorption and reaction of the target detection substance, thus greatly improving the sensitivity, response speed and detection limit of the sensor. Therefore, electrospinning PA nanometer arachnoid has a great application prospect in the field of high-performance sensors.

Figure 5 Schematic diagram of formaldehyde detection by colorimetric method based on nylon 6 nanometer arachnoid

3. Electrospinning PA process

3.1 Main materials and instruments:

(1) Spinning material: PA6 particles;88% formic acid, pure analysis.

(2) Experimental Instruments: 50mL conical flask, magnetic stirrer, electronic balance, E05 electrospinning machine.

(3) Protective equipment: rubber gloves, goggles, gas mask.

3.2 Spinning solution configuration:

Formic acid has strong corrosive and irritating odor, skin contact can cause inflammation and ulcers, we need to wear appropriate rubber gloves, protective goggles and gas masks and other protective equipment and improve the awareness of protection when operating the experiment !

Use an electronic balance to weigh a certain formic acid into a conical flask and stir on the magnetic agitator; then weigh PA6 of a certain quality, add it into the conical flask slowly, and cap the bottle tightly. After continuous stirring and dissolving for 6h, the particles are completely dissolved and the solution is clear and transparent, and a certain mass concentration of PA6 spinning solution can be obtained. The experiment needs to be arranged in a ventilated kitchen or a well-ventilated laboratory.

The mass concentration of PA spinning solution is commonly 8%-20%; The solvent systems are formic acid, hexafluoroisopropanol, formic acid/hexafluoroisopropanol (4:1), formic acid/acetic acid (4:1, 1:2), formic acid/dichloromethane (1:1) and formic acid /DMF (6:1).

3.3 Spinning process and parameters:

The PA spinning solution is pumped into a 20mL syringe, which is fixed to the syringe pump of the spinning machine, and a 20G (1/2inch, flat mouth) stainless steel needle is installed. The needle is connected to the positive pole of the high voltage power supply, the receiving roller is connected to the negative pole of the high voltage power supply, and the receiving base material is affixed to the receiving roller. Adjust the receiving distance to 15-20cm; Set the syringe specification as 20mL, the liquid supply speed as 1mL/h, the roller speed as 300 RPM, the slide stroke as 20cm, the spinning voltage as positive 15kV and negative 5kV, the temperature as 35℃, the humidity as 40%, and the timing as 120min.Finally, close the equipment door, open the exhaust air, and keep the room ventilated.

Common electrospinning receiving substrate:Aluminum foil paper, release paper, non-woven cloth, screen cloth, etc. Aluminum foil paper has a good conductivity , high receiving efficiency, release paper is easy to uncover film, non-woven cloth (screen) can be used as the base material of filtration application. They can be selected according to the specific application needs.

4. Common spinning problems and solutions

(1) There were more beads on the fibers under scanning electron microscope:Generally, the PA concentration in the spinning liquid is too low, resulting in insufficient viscosity of the spinning liquid. It is recommended to continue to increase the PA concentration. Usually, with the increase of the concentration of spinning solution, the spinning products will be changed from micro and nano particles, beaded fiber, uniform fiber to coarse fiber; In addition, the molecular weight of PA is too small, and the insufficient entanglement of PA molecules in the solution will also lead to the production of strings of beads in the fiber. In this case, it is suggested to replace the raw material with a slightly higher molecular weight.

(2) In the spinning process, the needle tip hangs the silk or floats the silk:Generally speaking, the humidity in the spinning environment is too high, the spinning jet is hygroscopic and solidified in advance in the air and the charge on the fiber is neutralized, which leads to the decrease of the fiber's charge, the weakening of the tensile properties of the fiber, the weakening of the electric field force, and the adsorption to the receiving pole. You can try dehumidifier dehumidification or heating dehumidification.

(3) How should the skin be treated if it comes into contact with formic acid accidentally:Rinse immediately with plenty of water or with soapy water or dilute lye (concentration of sodium bicarbonate solution is about 1%), pay attention not to wipe with wet cloth, if it is still serious, you should seek medical advice after the above emergency treatment.