Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Abstract: The construction of the bone ligament interface adopts a variety of strategies, which is of great value for tissue regeneration and understanding the mechanism of interface regeneration. However, it is still a challenge to summarize the complexity and heterogeneity of the natural bone ligament interface, including structural, cellular, and mechanical gradients. In this work, a bionic mesh convoluted micro pattern made by melt electrospinning (MEW) is proposed to simulate the natural structure of the bone ligament interface. The printing strategy of crimp fiber micro pattern was developed and the process parameters were optimized to simulate the crimp structure of collagen fibers in ligaments. The effects of curl angle and fiber spacing on the orientation of fibroblasts were studied.

Background: So far, the clinical treatment of ligament injury and the regeneration of ligament to bone connection is still challenging in orthopedics. Therefore, the construction of bone ligament interface structure in vitro not only has important value for the development of tissue grafts and the regeneration of damaged interfaces but also helps to better understand the structure-function relationship and the mechanism of interface regeneration.

Research highlights: Melt electrospinning writing (MEW) is a new 3D printing technology, which can produce microfiber patterns with predetermined geometry by controlling the printing plate Because of its versatility, it has been widely used to manufacture structures and scaffolds for various tissue engineering applications. Considering the printing flexibility of mew, the feasibility of MEW printing crimped fibers and the advantages of the new mesh structure in osteogenesis. In this study, a biologically inspired mesh curl micro pattern was made with mew to simulate the natural bone ligament interface structure. Firstly, a new writing method based on crimp fiber is developed and optimized.

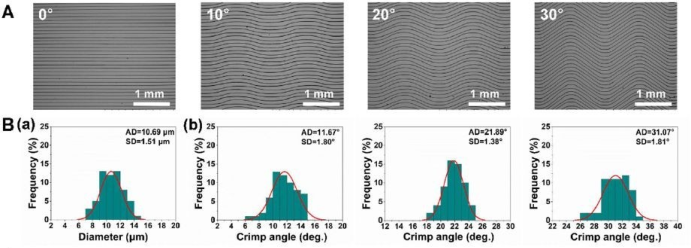

First, select the air pressure of 16 kPa and the collector speed of 7mm/s to print the following curl pattern. The crimp fiber micro pattern with different preset crimp angles ranges from 0 ° to 30 °. The parameters of the crimped fibers are similar to those of the natural collagen fibers in the ligaments, suggesting that the new model is a good reference for imitating the crimped fiber pattern of the ligament structure. To study the effect of curl angle on cell orientation, NIH/3t3 fibroblasts were cultured on micropatterns with curl angles of 0 °, 10 °, 20 °, and 30 ° respectively, and characterized by cytoskeleton immunostaining after 2 days of culture. (as shown in Figure 1) it shows that straight fibers and coiled fibers have an obvious guiding effect on cell orientation and morphology. The arrangement was further quantitatively evaluated by measuring the orientation angle of cells, that is, the angle between the direction of nuclei and the main direction of fibers. The statistical results showed that the cell orientation angle and fiber curl angle showed good consistency.

Figure 1 (a) SEM image, (b) - (a) fiber diameter distribution and (b) - (b) curl angle distribution of new crimp fiber pattern with different curl angles

In our study, after optimizing the new processing parameters, the fiber spacing can be as small as 50 μm, which will be more conducive to cell arrangement. The distance between NIH/3T3 cell skeleton and fiber is 50、100 and 200μm. The curly micro patterns of M show different degrees of arrangement. With the increase of fiber spacing, the cell arrangement effect of micropatterns was observed to be weakened. As expected, micro patterns with fiber spacing of 50μm showed the strongest guiding effect on cell orientation than those with fiber spacing of 100μm and 200μm. Using the optimized process parameters, new crimp fiber micro patterns with different crimp angles (0 – 30 °) and fiber spacing (50 – 200μm) can be successfully prepared. These two micro patterns have a certain impact on the guidance of cell orientation.

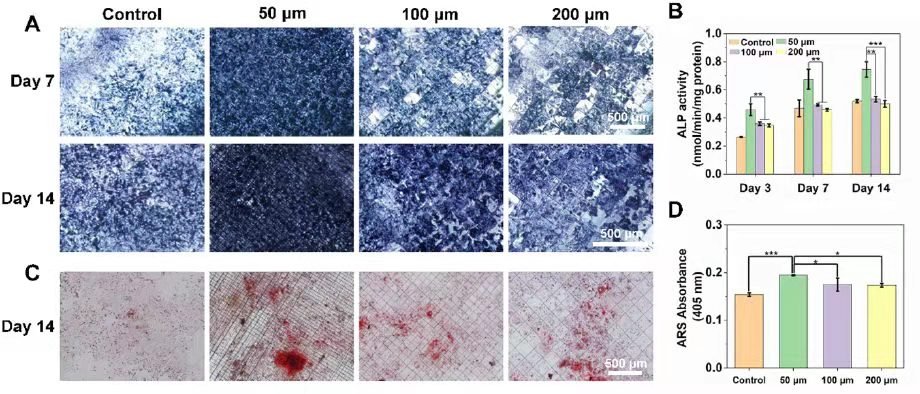

The grid micropatterns with different fiber spacing prepared above were used to culture human osteoblast Saos-2 cells. Figure 3 (a) shows the osteogenic induction of representative ALP staining images after 7 and 14 days. Fiber spacing is 50 μm The new grid micropattern of M resulted in the significant highest expression of ALP, and the expression of ALP in each group increased with time. Compared with the control, the new grid micropatterns showed greater mineralization and better osteogenic activity, especially with a 50μm fiber spacing pattern, which can be attributed to the 3D morphology of the micro pattern and the resulting increase in the specific surface area of cell growth. Moreover, the new grid coiled tubular scaffold can meet the morphological and mechanical requirements of natural bone ligament interface tissue, showing a good potential for bone ligament interface tissue engineering.

Figure 3 with different fiber spacing (50, 100 and 200 μ m) The osteogenic activity of the new mesh micropattern. (A) ALP stained images on days 7 and 14. (B) ALP semi quantitative results on days 3, 7 and 14. (C) Ars stained images on the second day 14 (D) Ars semi quantitative results on day 14

Conclusion: MEW has successfully fabricated a mesh curl multiphase micro mode to simulate the structure of the natural bone ligament interface. The strategy of manufacturing crimp fiber micro pattern was developed and the parameters including air pressure and collector speed were optimized. The fiber spacing is 50-200 μ M, and showed better osteogenic activity than the control, especially at a spacing of 50 μ M. The grid convoluted micropatterns with different fiber spacing were used in the co-culture of NIH/3t3 cells and Saos-2 cells. The results of cell migration showed that the smaller fiber spacing resulted in faster migration and earlier cells meeting in the interface region. By rolling up the new grid curling micro pattern, the 3D tubular three-phase scaffold was finally generated, showing the structural and mechanical similarity with the natural bone ligament tissue, which is expected to be used as a new scaffold for the study of bone ligament interface regeneration in vivo in our future research.

Reference:Xiong J, Wang H, Lan X, et al. Fabrication of bioinspired grid-crimp micropatterns by melt electrospinning writing for bone–ligament interface study[J]. Biofabrication, 2022, 14(2): 025008.

DOI:https://doi.org/10.1088/1758-5090/ac4ac8

This article is the latest research result published by the Nanofiberlabs team in the journal Biofabrication. Bioprinting materials have broad application prospects in future medical and clinical applications. M08-001 is a near-field electrostatic direct writing equipment developed by Nanofiberlabs. It can prepare highly oriented nanofibers by near-field direct-writing electrospinning technology, realize solution near-field spinning or fusion near-field direct writing, and print for biological tissue repair. Materials for vascular repair, skin repair, biopatches and other applications. Exclusive patented technology, the printing accuracy can reach nanometer level. It is a powerful tool for micro and nano manufacturing.