Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Electrospinning method is divided into solution electrospinning method and melt electrospinning method according to the difference of the properties of polymer raw materials. At present, solution electrospinning has realized the mass production of nanofibers. However, solution electrospinning has a high cost due to solvents, and inevitably has toxicity (such as dimethylformamide, methylene chloride), which hinders the combination and application of many fields. The melt electrospinning does not require solvents, and it is a very safe and green spinning process. Therefore, this article briefly describes the melt electrospinning technology and its applications.

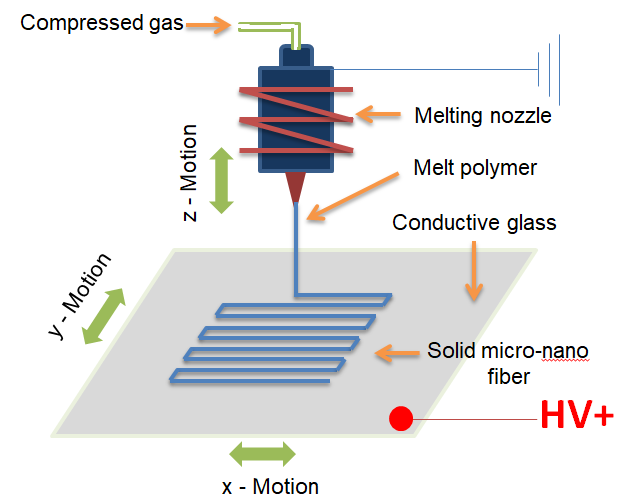

Melt electrospinning is a technology that directly melts polymers and electrospun them to form fibers under high temperature conditions. Usually the melt electrospinning device is composed of a feeding mechanism, a heater, a nozzle, a high-voltage power supply, and a collecting plate.

Figure 1 Diagram of Melt Electrospinning Device

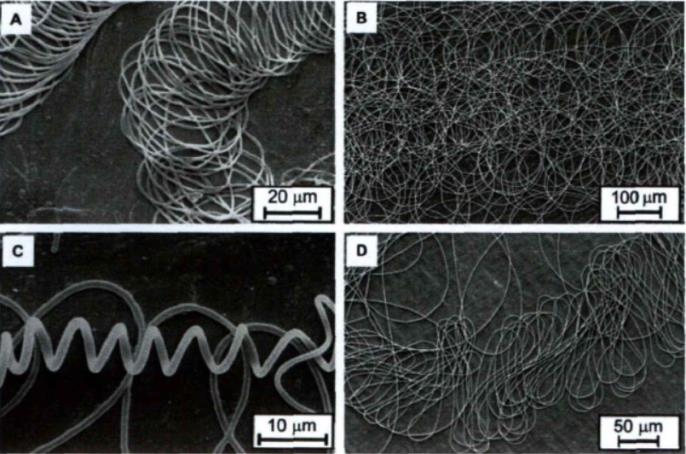

The polymer melt has higher viscosity and lower conductivity, making the fiber diameter prepared by melt electrospinning larger than that prepared by solution electrospinning, which hinders its further development. At present, there is still a lack of theoretical research on melt electrospinning in the world, and further research is needed on both the device structure and the electric field mechanism. The morphology of the melt electrospinning fiber is generally round, as shown in the figure below.

Figure 2 Microscopic image of melt electrospinning

Researchers have made improvements to equipment and devices in terms of improving spinning efficiency. Traditional melt electrospinning is a capillary type, which can only produce a single jet, and the efficiency is low. Therefore, researchers at the Asian University of Technology in Germany proposed an array of capillary tubes to increase the spinning efficiency.

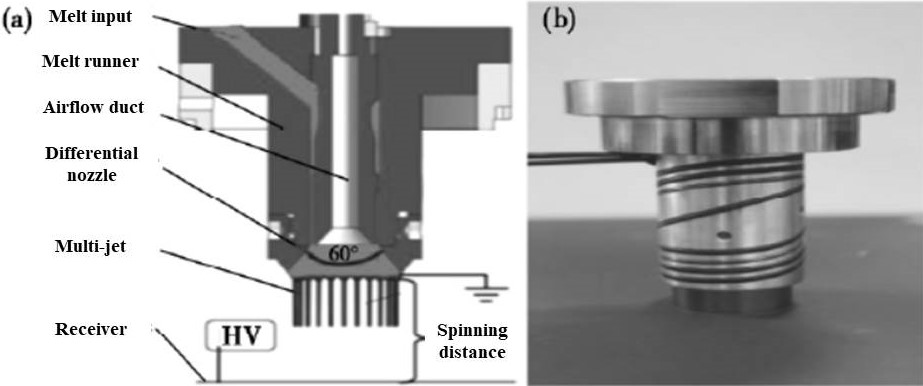

Professor Yang Weimin of Yinglan Laboratory, School of Mechanical and Electrical Engineering, Beijing University of Chemical Technology, was inspired by nature’s waterfalls. Based on the idea of advanced polymer manufacturing calculus, his team proposed the melt differential electrospinning technology for the first time and innovatively designed umbrellas. Compared with the single-needle capillary nozzle, its spinning efficiency is increased by 80 times. The nozzle structure is shown in Figure 3.

Figure 3 Melt micro spinning nozzle

Melt electrospinning is divided into near-field and far-field. The near-field melt electrospinning technology is based on melt electrospinning and proposes a lower pressure, safer and more environmentally friendly spinning method. The basic principle is to reduce the spinning voltage by reducing the spinning distance (a few centimeters or even a few millimeters of scale). In the process of near-field direct-write melt electrospinning, the spinning jet is less affected by environmental humidity and temperature. Therefore, during the spinning process of melt electrospinning, the stable spinning area in the straight segment is longer and the length can reach About 3cm, the deposition of spun fibers can also be precisely controlled.

According to existing research, as a technology with unlimited development prospects, melt electrospinning has good fusion. The near-field melt electrostatic direct writing technology is a new process that has emerged in recent years. It is used to prepare porous scaffolds for tissue engineering. The prepared fibers reach the nanometer or micrometer scale, and the structure is similar to the natural extracellular matrix. It has the most potential. The tissue engineering scaffold materials can be used for 3D bioprinting, such as functional membranes, cell scaffolds, cell carriers, blood vessel transplants, and so on. As the range of thermoplastic and functional polymer materials suitable for melt electrospinning continues to expand, the application fields of near-field melt electrospinning will soon be expanded. Therefore, it can be expected that near-field melt electrospinning will become a promising bio 3D printing technology.

Foshan Nanofiberlabs Co , Ltd has developed the near-field direct-write electrospinning machine, which is a new type of equipment developed based on the melt electrospinning technology. Interested parties are welcome to contact us! Product Links:https://www.nanofiberlabs.com/product/3d-printing-technology-electrospinning-machine-m08.html

Figure 4 3D printing technology electrospinning machine - M08