Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Catalogue

1. Research background of high efficiency and low resistance air filter materials

2. Advantages of electrostatic spinning for preparing high efficiency and low resistance air filter materials

3. High efficiency and low resistance filtering mechanism of electrospun air filter material

4. Design of functional electrostatic spinning air filter material

1. Research background of high efficiency and low resistance air filter materials

In recent years, the rapid development of global industry has led to the worsening of the global environment and increasingly serious air pollution. What's worse, the outbreak and continuous mutation of new coronavirus diseases pose a serious threat to public health. Therefore, air filter materials have become the key to personal protection.

In this environment, electrospun nanofiber membrane with high filtration efficiency and low resistance has been widely studied, because it can simultaneously meet the requirements of users for filtration and comfort. However, for personal protection, the evaluation of air filter materials should consider the comprehensiveness of protection and higher comfort in practical application. Therefore, on the basis of high filtration efficiency and low resistance, more functions should be given to personal protective high-performance air filter materials.

2. Advantages of electrostatic spinning for preparing high efficiency and low resistance air filter materials

Electrospinning is a universal and low-cost method for preparing nanofiber membranes, with large surface area, small pore diameter, controllable fiber diameter (especially for stable preparation of nanofibers below 100nm) and high yield. In addition, a wide variety of materials can be used for electrospinning, including various polymers, small molecules, ceramics, etc., which makes it possible to rapidly prepare nanofibers with various structures and functions. Therefore, more and more studies have shown that electrospun nanofiber membranes can be manufactured to achieve high-performance air filtration and used for personal protection.

3. High efficiency and low resistance filtering mechanism of electrospun air filter material

Based on the classical single fiber filtration model, the high efficiency and low resistance air filtration process of electrospun fiber membrane will be better clarified by combining the analysis of air flow field with the perspective of membrane filtration process. Specifically, the realization of efficient and low resistance air filtration can be attributed to three mechanisms: enhanced electrostatic effect, excellent slip effect, and rough fiber surface. The three mechanisms will jointly promote the improvement of air filtration performance.

4. Design of functional electrostatic spinning air filter material

Nowadays, as people pay more and more attention to personal protection, the use of air filter materials is becoming more and more frequent, and a single filter performance can no longer meet the demand. People began to pay more attention to how to maximize the benefits and use of personal protection.

Enhanced electrostatic adsorption capacity, slip effect and improvement of fiber roughness are the three main mechanisms to achieve high efficiency and low resistance air filtration.

4.1 High dust volume

The dust holding capacity refers to the particle mass that can be captured when the pressure drop reaches twice the initial value. During use, particles will continuously deposit on the surface or inside of the air filter material, thus affecting the air circulation. Therefore, high dust capacity can ensure comfortable personal protection for a long time without worrying about changing filter materials in hazardous environments. Generally speaking, the dust holding capacity of filter materials relying on surface filtration is small, while that relying on deep filtration is large, because the former is easy to cause blockage and the pressure drop rises sharply; The latter relies on tortuous three-dimensional channels and is not easy to block. Therefore, the deep filtration of air filter material is the key to improve the dust holding capacity. Gradient structure is an effective method to realize depth filtering.

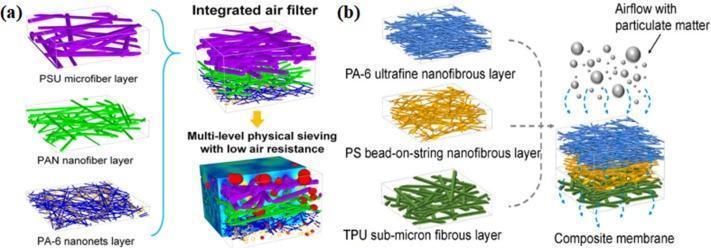

Fig. 1 (a) Structural diagram of multistage PSUPANPA-6 membrane, realizing the effect of one plus one more than two: more efficient filtration efficiency and smaller pressure drop. (b) TPUPSPA-6 composite membrane structure diagram, for 0.3 μ The filtration efficiency of m NaCl particles is 99.99%.

4.2 Water vapor transfer

During the use of air filter materials, the exhaled water vapor may cause uncomfortable feelings. For hydrophobic materials, low water vapor permeability will cause a sense of humidity, while for hydrophilic materials, water will be absorbed to form a liquid film, which will rapidly increase the air resistance. The purpose of the water vapor transmission system is to achieve efficient directional transfer of water droplets and water vapor, so as to avoid rising air resistance and wet viscosity caused by exhaled water vapor.

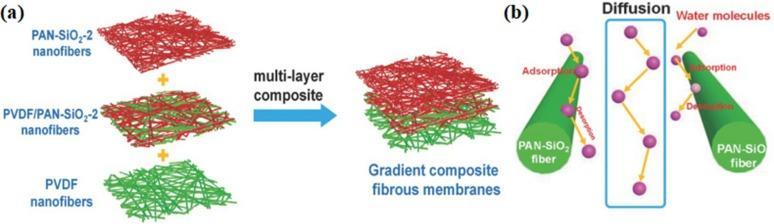

Constructing hydrophobic/hydrophilic gradient structure is an effective way to realize the directional transport of water droplets or water vapor. Now more and more scholars have prepared air filtering materials with better filtering performance, such as water vapor or water droplets.

Fig. 2 (a) Schematic diagram of the manufacturing process of gradient composite fiber membrane. (b) The mechanism of transferring water molecules.

4.3 Antibacterial activity

Particles in the air usually contain a large number of bacteria, which pose a potential risk to human health. Therefore, the antibacterial performance of air filter materials has become a research hotspot, which can prevent people from being injured by bacteria.

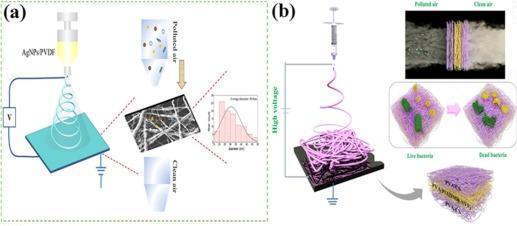

At present, most antibacterial materials are mainly based on the adsorption and dissolution of cationic ions on negatively charged bacterial cell membranes and cell walls. In addition, polymers extracted from some natural herbs have also been proven to achieve antibacterial functions by targeting specific bacterial groups. In contrast, metal and its oxide nanoparticles have better antibacterial properties because they are easier to ionize.

Fig. 3 (a) Dendriform bimodal PVDF nanofibers containing silver nanoparticles have high filtration performance for Staphylococcus aureus and Escherichia coli. (b) A multilayer bimodal nanofiber membrane composed of PVA, CS and N-haloamines (PVA/CS/N-haloamines) was prepared, which has obvious inhibitory effect on Escherichia coli and Staphylococcus aureus.

4.4 Absorption of gaseous pollutants

Gaseous pollutants are pollutants that exist in the molecular state under normal conditions. Most of them have unpleasant odor, toxicity, irritation, teratogenicity and carcinogenicity, and will cause great harm to human health. It can prevent human health from being endangered by making air filter materials have the adsorption capacity of gaseous pollutants.

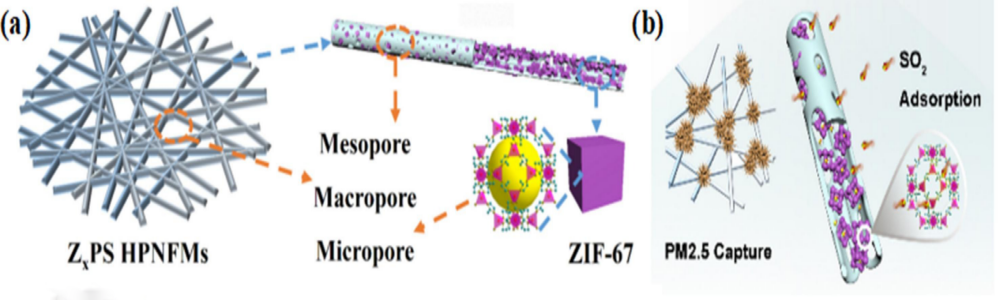

The introduction of components that can interact with gas pollutant molecules into electrospun fibers will greatly improve the gas pollutant adsorption capacity of the prepared filter materials. The key to improve the adsorption capacity of gaseous pollutants is the high specific surface area of the adsorbent and its possible contact with the gas.

Fig. 4 (a) Structure of PS/ZIF-67 porous nanofibers. (b) PS/ZIF-67 fiber filtration and SO2 adsorption process.

Although the multifunctional electrospun air filter materials for personal protection have made great progress, there are still many challenges: (1) The mechanical properties of existing electrospun filter materials are often insufficient. (2) The use of degradable materials and green solvents to prepare electrospun filter materials can reduce the environmental burden, but these materials often do not have enough electrospun performance, and the filtering performance of the prepared filter materials is difficult to guarantee. (3) Based on the existing research, more performance exploration and in-depth research are needed to further improve the protection effect. (4) The realization of multi-function usually requires more preparation processes. Therefore, it is necessary to find the simplest preparation method (one-step preparation) to promote its batch preparation and industrial production process. (5) Effectively predict the service life of high-performance air filter materials (including the service life of filter materials and other functions) to avoid the danger caused by the attenuation of protection performance or discomfort caused by the attenuation of other functions.

Reference: doi.org/10.1016/j.seppur.2022.122175

Profile of Professor Zheng Gaofeng

Associate Professor, Associate Director, Doctoral Advisor, Department of Instrument and Electrical Engineering, Xiamen University, Institute of Aeronautics and Astronautics. He published more than 130 academic papers included in SCI and EI, applied for more than 50 invention patents as the first inventor, authorized more than 30 invention patents, 30 utility model patents, published one monograph, and participated in writing three monographs. He has presided over such vertical projects as the National Natural Science Foundation of China, Fujian Provincial Key Industry and Science Research Projects, Fujian Provincial Natural Science Foundation, Guangdong Provincial Natural Science Foundation, the Doctoral Program Fund of the Ministry of Education, and Xiamen Science and Technology Program, and has undertaken more than 20 technology development projects entrusted by enterprises; As a research backbone, he has participated in the research work of many national, provincial and ministerial key projects. Mainly engaged in micro nano jet printing, electrostatic spinning, industrial automation, advanced control technology, micro system integration applications and other fields.