Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Introduction: To reduce carbon emissions and achieve "carbon neutrality", strategies can be formulated from four directions: carbon substitution, carbon emission reduction, carbon storage and carbon cycle. In recent years, the application of clean energy such as solar energy, wind, tidal energy and photovoltaic energy has increased dramatically, reducing the environmental pollution caused by traditional energy. These new energy industries are also the key industries of carbon substitution strategy. The key to energy transformation is to be able to develop and use new energy on a large scale. At present, China's industrial system on new energy is also gradually growing, and great progress has been made in the industries of electric vehicles, lithium batteries, photovoltaic power generation, etc. At present, the research of electrospinning nanotechnology in new energy has also been paid more and more attention. This paper shares 5 articles on the research of electrospinning technology in new energy.

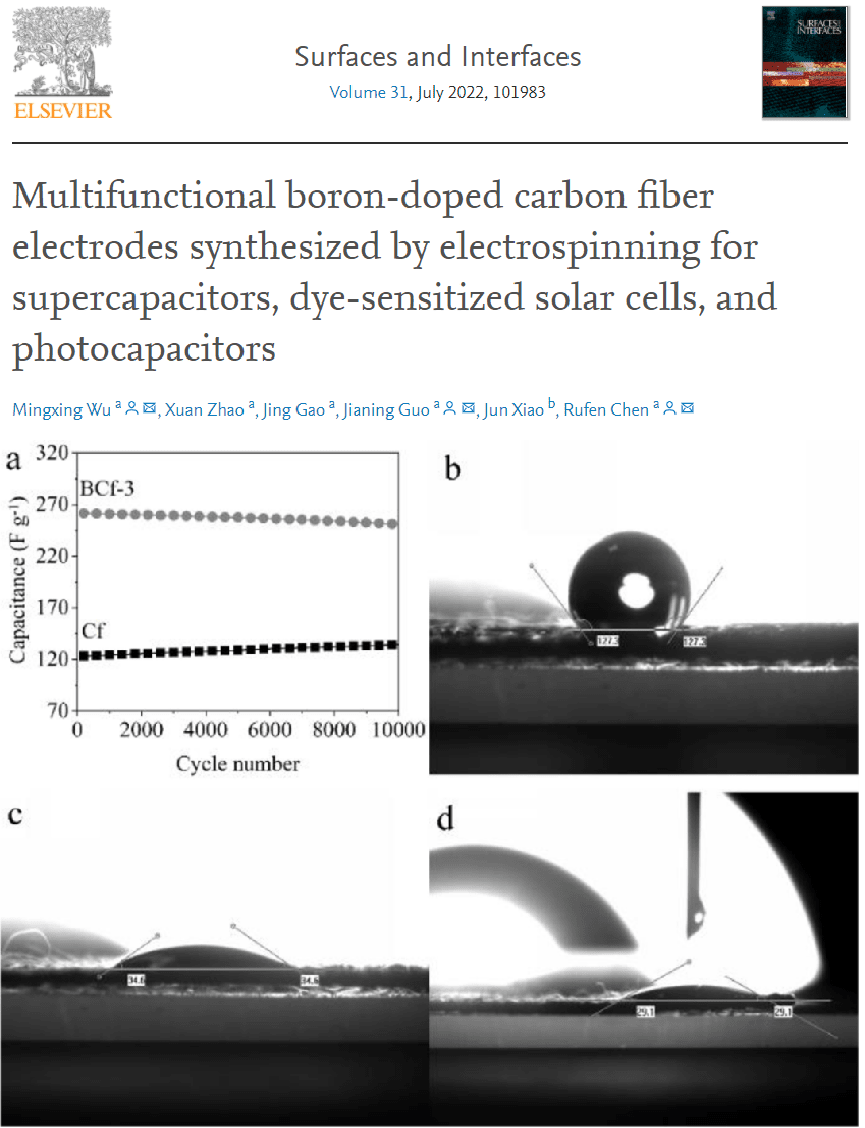

1.Professor Wu Mingxing's team of Hebei Normal University: multifunctional boron doped carbon fiber electrodes for supercapacitors, dye-sensitized solar cells and photoelectric containers prepared by electrospinning

▷ How to use solar cells to generate electricity economically and efficiently and make use of this energy conveniently is of great significance to energy conservation and emission reduction, environmental protection and sustainable development. Photocell is a self charging integrated device composed of dye-sensitized solar cell (DSC) and supercapacitor.

▷ Synthesis of boron doped carbon fiber (BCF) as a multifunctional electrode material for supercapacitors and dye-sensitized solar cells (DSC), as well as a photoelectric container made of supercapacitors and DSC.

▷ After optimizing the amount of boron source, the specific capacitance of BCF electrode reached 309.0f g − 1, which was much higher than that of original carbon fiber (CF) electrode (172.8f g − 1) The performance of DSC using BCF as counter electrode is also better than that of CF. the power conversion efficiency of DSC using BCF as counter electrode is 7.51%.

▷ The photoelectric container based on BCF shared electrode achieves 1.19% total energy conversion and storage efficiency, which is much higher than that of the photocell using CF electrode (0.70%). Boron doping improves the wettability, mass transfer and charge transfer properties of BCF, thus improving its electrochemical performance.

DOI:doi.org/10.1016/j.surfin.2022.101983

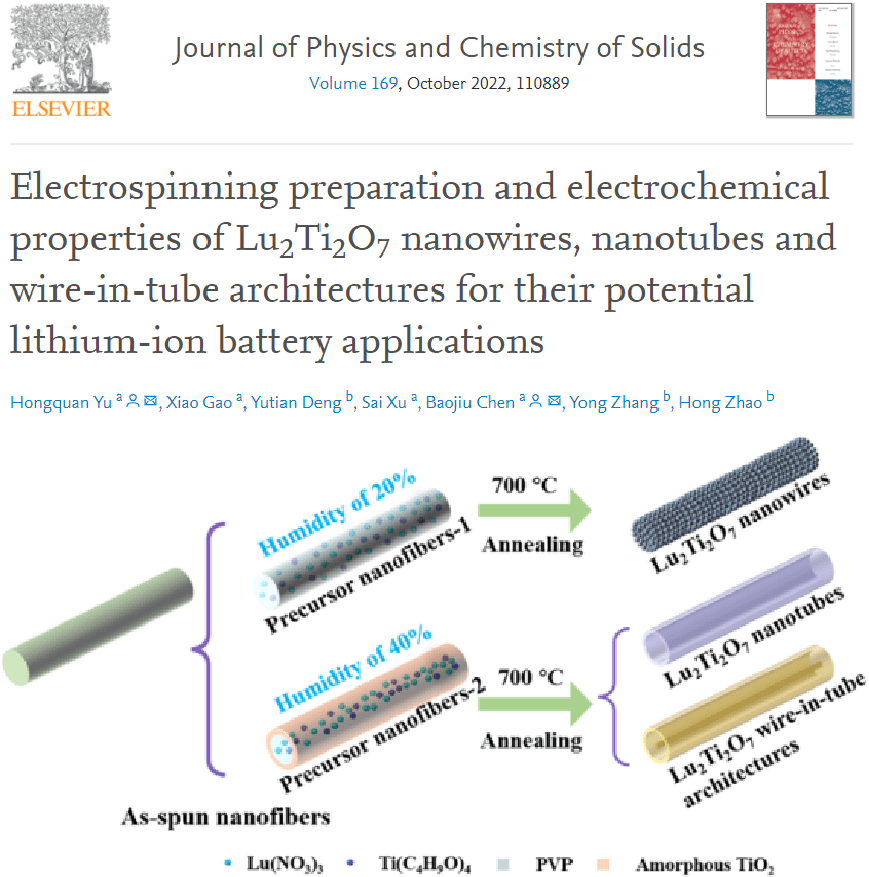

2. Team of Professor Yu Hongquan from Dalian Jiaotong University: electrospinning preparation and electrochemical performance of lu2ti2o7 nanowires, nanotubes and tube line structures and their potential applications in lithium ion batteries

▷ In recent years, the application of clean energy such as solar energy, wind energy and tidal energy has surged, because of the need to prevent environmental pollution caused by the use of traditional energy and the significant energy crisis caused by the current shortage of fossil fuels. Energy storage technology plays a "bridge" role. It is more and more important to find new electrode materials for high performance energy storage devices.

▷ Electrospinning is used to manufacture one-dimensional functional nanostructures, such as nanowires, nanotubes, nanobelts and nanofibers. By adjusting the spinning solution and environmental parameters, solid nanofibers with metal oxide, carbon and multicomponent systems were synthesized using a single needle.

▷ By controlling the environmental humidity, lu2ti2o7 nanowires, nanotubes and tube line structures were prepared by simple single needle electrospinning technology. Lu2ti2o7 nanowires with a diameter of about 150 nm were formed at 20% atmospheric humidity. Lu2ti2o7 nanotubes and wires in tubes were obtained at 40% atmospheric humidity.

▷ The specific capacity of lu2ti2o7 nanotube and in tube wire structure is 167.35mah · g − 1, while the current density of lu2ti2o7 nanowire is 143.45mah · g − 1. When the current density is 100 Ma · g − 1, it is used as the negative electrode material of lithium-ion battery after 50 charge and discharge cycles. Compared with lu2ti2o7 nanowires, lu2ti2o7 nanotubes and tube line structures have better cycle stability and rate performance.

DOI:doi.org/10.1016/j.jpcs.2022.110889

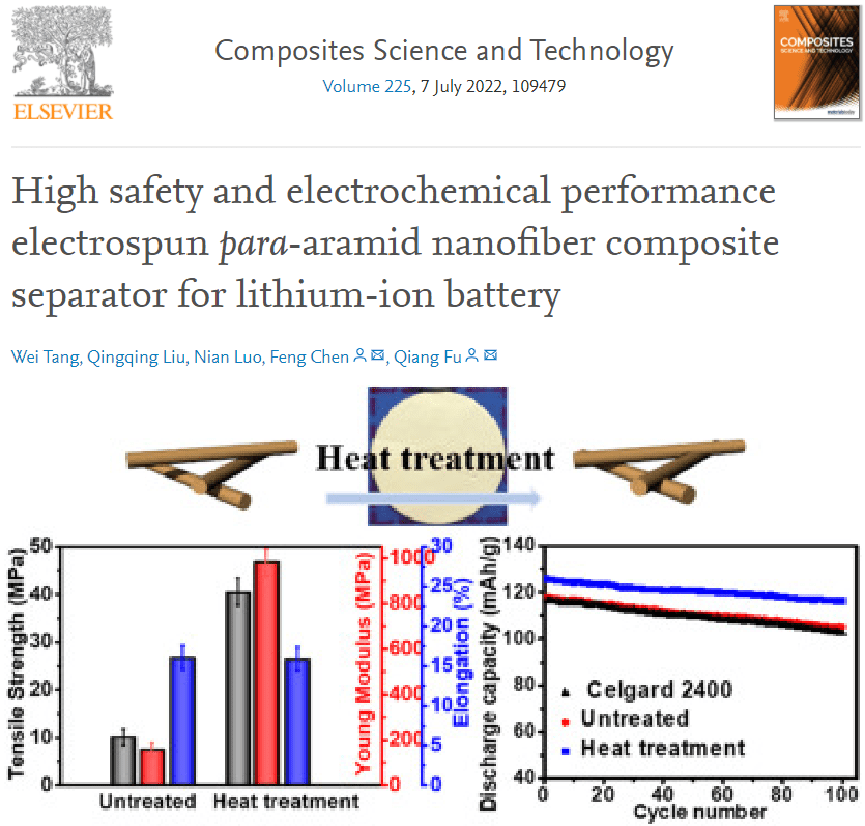

3. Professor Fu Qiang's team of Sichuan University: electrospun aramid nanofiber composite membrane with high safety and electrochemical performance for lithium-ion batteries

▷ The separator has an important impact on the electrochemical performance and safety of lithium-ion batteries. So far, it is still a great challenge to prepare a separator that can meet all the requirements of LIBS.

▷ Here, a porous composite membrane based on Para aramid nanofibers (ANFs) was successfully prepared by electrospinning and applied to the lithium ion battery separator. The obtained ANFs / PEO separator has good morphology and high porosity. Therefore, cells with ANFs / PEO separators showed better electrochemical performance than Celgard 2400 separators.

▷ More importantly, the tensile strength of ANFs / PEO separator after heat treatment reaches 41.52 MPa, which can maintain a porosity of 75.85%. Meanwhile, the thermal stability of ANFs / PEO separator is outstanding. Compared with Celgard 2400 separator, ANFs / PEO separator has better electrochemical performance and thermal stability, as well as good mechanical strength and flexibility, achieving a balance between the electrochemical performance and safety of LIBS.

▷ These results indicate that ANFs / PEO separators with comprehensive performance are expected to be used for high-performance LIBS.

DOI:doi.org/10.1016/j.compscitech.2022.109479

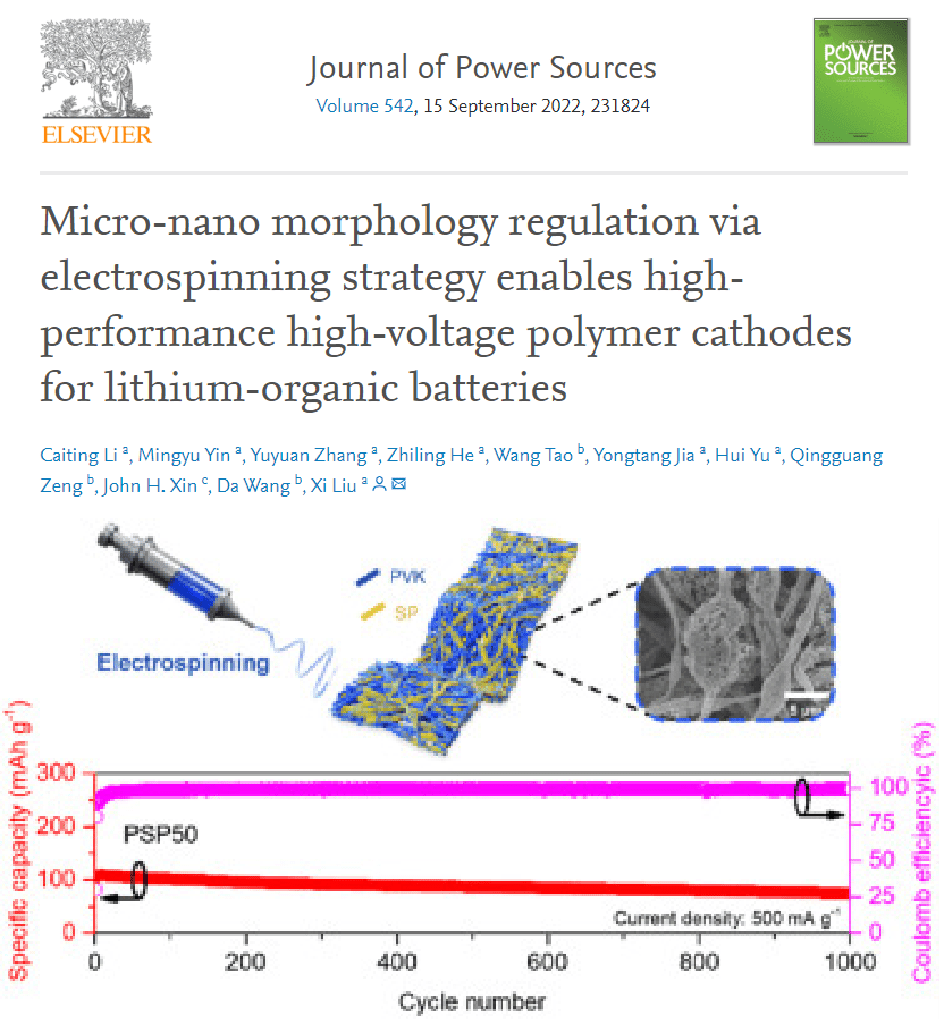

4. Professor Liu Xi's team of Wuyi University: realized the high-performance high-voltage polymer cathode of lithium organic battery through the micro nano morphology adjustment of electrospinning strategy

▷ Organic / polymer cathodes have attracted more and more attention due to their multifunctional structure, low cost, easy synthesis and environmental friendliness. However, the high viscosity of polymers makes it a major challenge to achieve operable morphology in organic / polymer: conductive agent composites.

▷ In response, this paper introduces a new electrospinning strategy for controlling the micro and nano morphology of p-type high-pressure polymer poly (N-vinyl carbazole) (PVK) and carbon black super P (SP).

▷ The PVK based fiber cathode (psp50) prepared by this strategy has fine 3D nanopore structure, fast ion / electron transport characteristics and ultrafast reaction kinetics. Compared with the PSP electrode made by traditional method and coating (PSP CO), psp50 has high discharge capacity, significant rate capacity and excellent cycle stability.

▷ This study provides a new direction for adjusting the micro nano morphology of the organic cathode of high-performance lithium organic batteries.

DOI:doi.org/10.1016/j.jpowsour.2022.231824

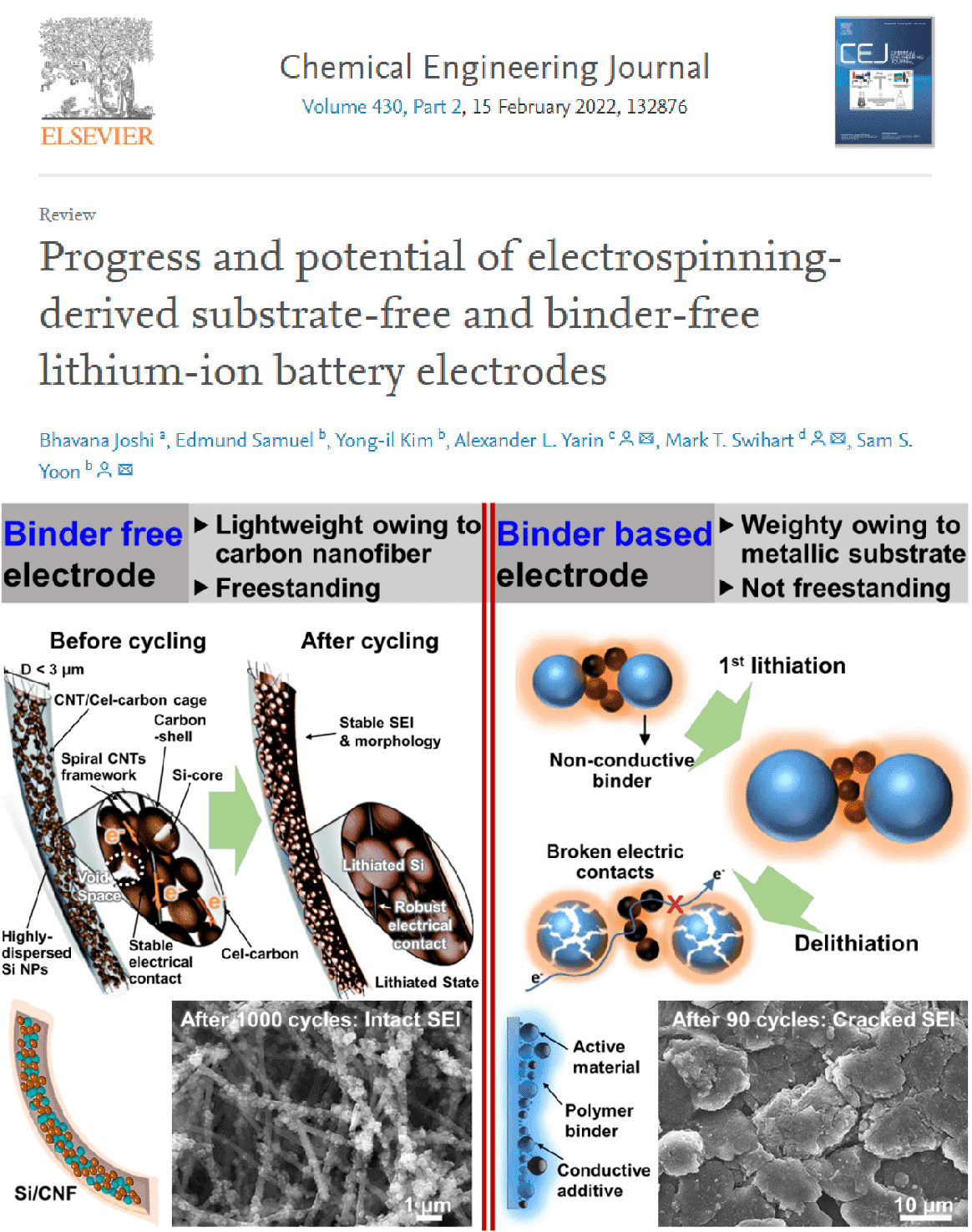

5. State University of New York, buffalo, mark t Professor swihart's team: progress and potential of electrospinning derived substrate free and adhesive free lithium ion battery electrodes

▷ Carbon nanofibers prepared from electrospun precursors show great prospects in electronic applications due to their flexibility, conductivity, high specific surface area and open structure.

▷ Integrating metal oxides and sulfides into carbon nanofibers instead of using them with other binders eliminates many problems caused by poor adhesion, agglomeration of nanomaterials, excess mass caused by inactive binders, and low conductivity of embedded active materials.

▷ This paper discusses the engineering design of electrospun fibers with new morphology, such as core-shell structure, hollow structure or porous structure, and the use of decorative carbon nanofibers (such as through electrodeposition or coprecipitation). A representative schematic diagram of the lithium storage mechanism of these binder free electrodes is given. We describe how electrospinning technology provides a cost-effective strategy for manufacturing light lithium ion batteries with high capacity and excellent flexibility.

▷ This review introduces the fascinating morphology of these specially designed carbon nanofiber electrodes, which enhance the electrochemical performance of metal oxides and sulfides, and illustrates their great potential in wearable electronic devices and hybrid electric vehicles.

DOI:doi.org/10.1016/j.cej.2021.132876