Printing accuracy down to nanometer scale, adjustable and controllable nanofibre diameter;

Automatic calibration function, save research time;

Platform repetitive motion accuracy improved to sub-micron level;

Original software algorithm, print path can be designed, support custom pattern printing, straight line and curve printing;

Higher precision print vision, capture the printing process and details;

Graphics format: Support vector, bitmap, built-in basic primitives.

Printing accuracy can be up to nanometers, diameter of nanofibers can be adjusted and controlled.

Automatic calibration function saves research time.

Platform repeatable motion accuracy improved to sub-micron level.

Unique software algorithm, print path can be designed, support custom pattern printing, straight line, curve printing.

Higher precision print vision, capture the printing process and details.

Graphics format: Support vector, bitmap, built-in basic primitives.

Better scalability: glove box, UV curing......

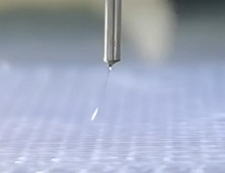

"Pull" : Through the electric field force, the ink is pulled down from the nozzle. Nozzle diamete:>100μm Ink viscosity:0.5~10000cPs Point diameter:1μm~ line width:≥0.5μm Droplet refinement:≥0.5fL |

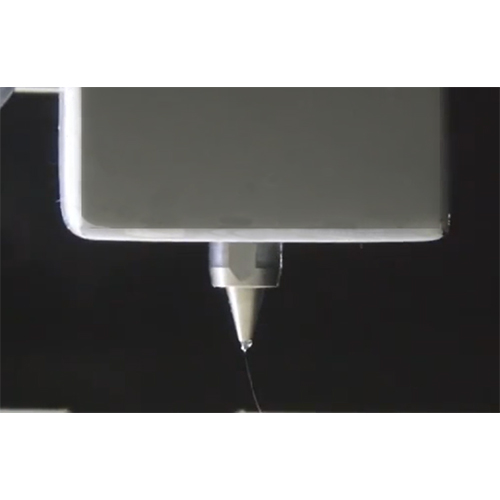

"Squeeze" : Push the ink out of the needle by adding a driving force to the solution. Nozzle diamete:<20μm Ink viscosity:~20cPs Point diameter:20μm Droplet refinement:≥1pL |