Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

The current development direction of warmth retention materials is lightweight and efficient. Traditional fiber warmth retention materials have large diameters, resulting in heavy material weight and limited improvement in warmth retention. Common advanced warmth retention materials (such as metal reflectors and electric heating) have defects such as high cost and insufficient safety. Therefore, the development of lightweight and efficient warmth retention materials are still a major problem at present. In this paper, an ultra light and super elastic electrospinning fibrous sponge with low thermal conductivity and high thermal storage was prepared by humidity-induced electrospinning.

Keywords: Humidity-induced; Fibrous sponges; Electrospinning; Warmth retention

High-performance warmth retention materials are an effective way to realize individual cold protection. Currently available fiber thermal commonly used materials include natural fiber (cotton, wool, feather, etc.) and synthetic based (ultrafine fibers, hollow fibers, etc.), the diameter of these fibers were 10 μm or more, to meet the need for warmth in extreme cold conditions , the usual method is to increase the weight and thickness of the material, but at the same time it will cause inconvenience to the wearer, especially the combat soldier.

At present, advanced warmth retention materials have been developed by scientific researchers and have attracted wide attention from academia and industry. For example, metalization of fabrics gives the materials high infrared reflection performance to prevent the human body from dissipating a large amount of radiant heat. The high thermal conductivity generated when the layer is in contact with the skin will lead to rapid conduction and dissipation of heat from the human body. At the same time, the metal layer has the disadvantage of being expensive. In addition, in order to expand more application scenarios, electric heating warmth retention materials have also been studied and reported, but such materials also face the defects of energy consumption and insufficient safety. Therefore, the development of safe and energy-saving lightweight and efficient warmth retention materials is still a major challenge.

Recently, the team of Academician Yu Jianyong and Ding Bin of the Textile Technology Innovation Center of Donghua University published a research paper entitled "Ultralight and superelastic fibrous sponges with effective heat preservation and photothermal conversion for personal cold protection" in the Composites Communications journal under Elsevier.This paper uses humidity-induced electrospinning technology (that is , spinning under high humidity ( ~85% ), the fibers will form a flocculent accumulation at the receiving end to form a three-dimensional fluffy sponge-like nanofiber mat) to prepare a ultra - light and super-elastic electrospun fibrous sponges with low thermal conductivity andhigh heat storage .

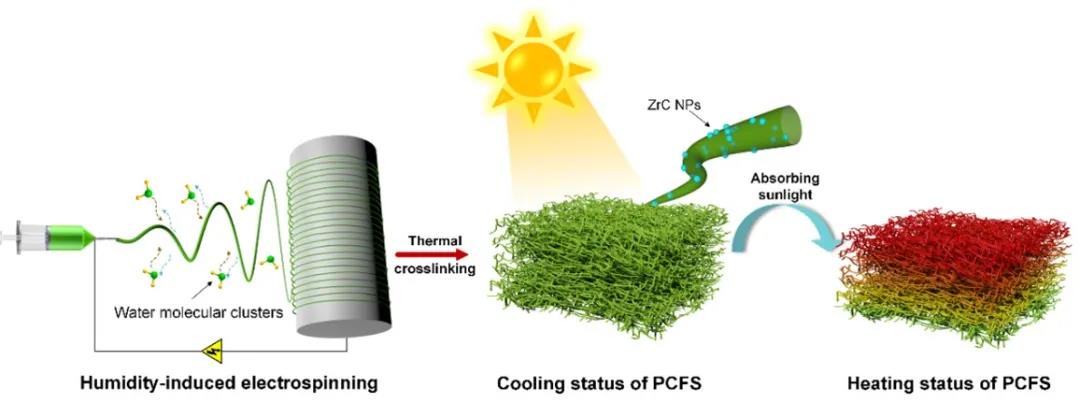

Figure 1 Schematic diagram of the preparation process of ultra - light and super-elastic electrospun fibrous sponges and its light-to-heat conversion performance

The electrospinning fabrication process of a fibrous sponge in Figure 1 , first developed a monomer prepolymer / linear polymers bicomponent new solution formulations, and the photothermal conversion material of zirconium carbidenanoparticles were introduced into the solution system.The humidity-induced electrospinning technology is used to prepare an electrospun fiber skeleton with a three-dimensional fluffy structure in one step, and then heat-treat it to produce a stable polymer cross-linked network inside the fiber to give the material good mechanical properties.

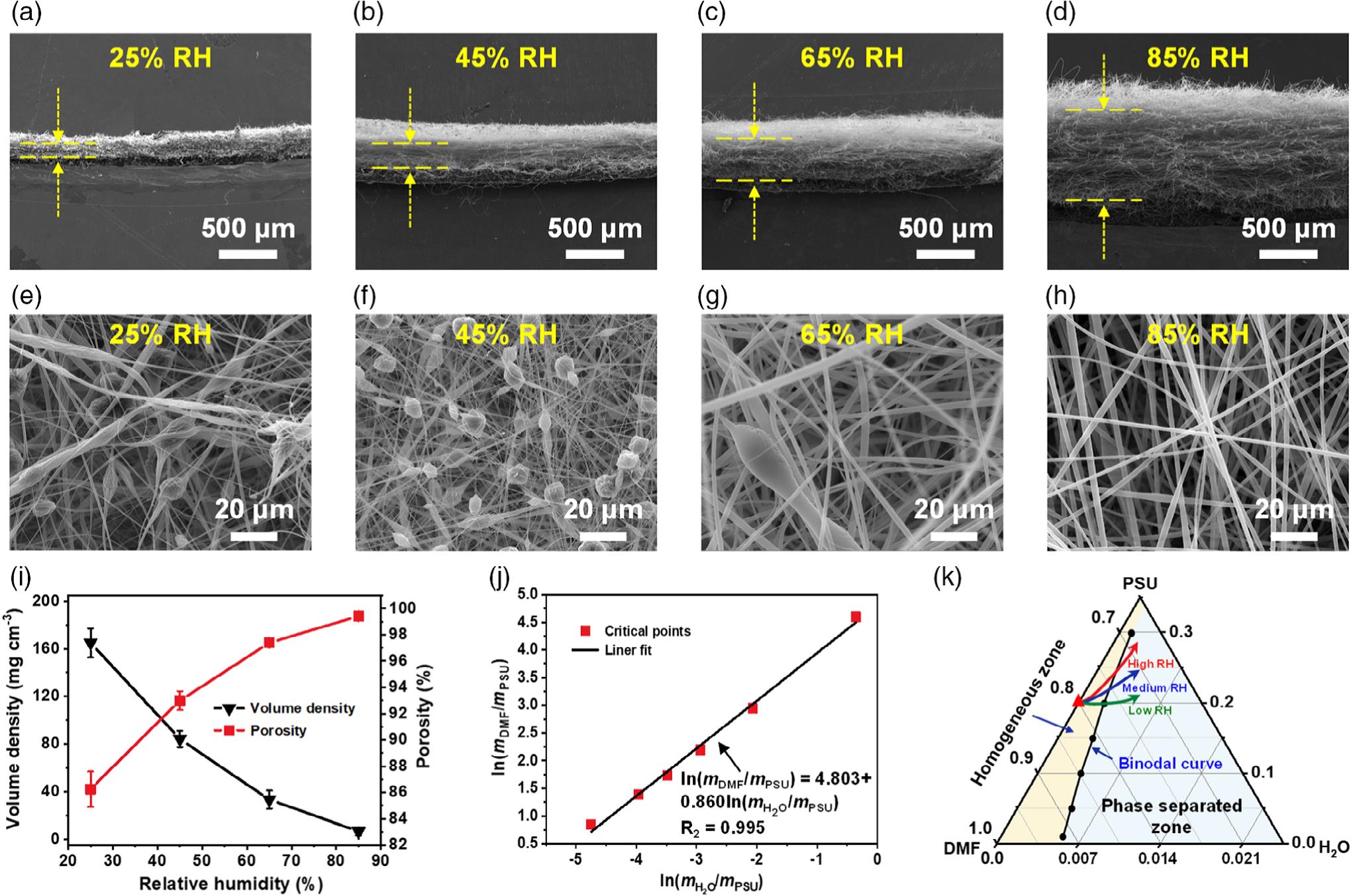

The process of humidity-induced effect on the formation of fluffy nanofibers is shown in Figure 2. Under low humidity, a dense nanofiber membrane is obtained. As the humidity increases, the fiber membrane gradually becomes fluffy, and reaches the maximum when the humidity is 85% . In addition, it is shown that humidity has a significant effect on the morphology of nanofiber beads, which is manifested by the fact that there are more beads in the fiber under low humidity. As the humidity increases, the surface of the fiber gradually becomes smooth.

Figure 2 Cross-sectional ( ad) and top-view ( eh) SEM images of PSU fibers prepared under different RHs . i) at different RHs the preparation of the PSU fiber bulk density and porosity. j) Linearized cloud point diagram of PSU-DMF-H2O system. k) Cloud point diagram of temary phasePSU-DMF-H2O system

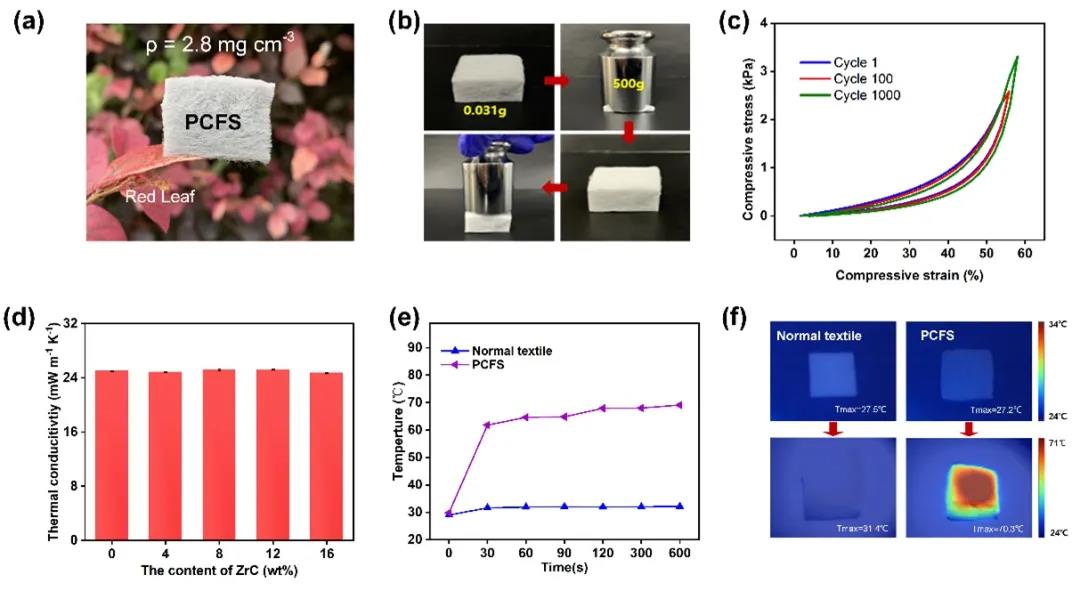

The average diameter of the fibers in the prepared electrospun fiber sponge is about 3 μm. The material can obtain extremely low thermal conductivity (~25.2 mW/m•K) under extremely low bulk density (~2.8 mg/cm3),which is close to the thermal conductivity of air under normal temperature and pressure , showing excellent resistance to heat loss; at the same time, under the irradiation of simulated sunlight, the surface temperature of the material can quickly rise to 60.8 ℃ within 30 seconds , and finally stabilize at 70.3 ℃, showing high efficiency of light-to-heat conversion performance, indicating that the material also has excellent heat storage and active warmth preservation function. In addition, the material can bear large deformation and compression under 10,000 times its own weight, and can quickly return to its original shape; at the same time, under a low temperature environment of -100 ℃, the material only exhibits very small plastic deformation after 1000 cycles of compression ( ɛ=60% ), indicates that the material has excellent low-temperature compression resilience (Figure 3). The fibrous sponges excellent overall performance make it exhibit broad application prospects in the field of cold-resistant and warm-keeping materials.

Figure 3 Characteristics of ultra - light super-elastic electrospun fibrous sponges: ( a ) ultra-light characteristics, ( b ) large deformation compression resilience ( c ) low-temperature compression resilience, ( d ) thermal conductivity of materials with different zirconium carbide content ( E ) Simulate the surface temperature of ordinary textiles and PCFS under sunlight ( f ) simulate the infrared imaging picture of the surface of ordinary textiles and PCFS after 10 minutes of sunlight .

In recent years, the team of academician Yu Jianyong and researcher Ding Bin has achieved fruitful results in the preparation of three-dimensional nanofiber sponges sound-absorbing and warm-keeping materials by humidity-induced electrospinning technology. According to incomplete statistics, the team has published 7 related papers from 2019 to 2021, including 3 in the first district, 4 in the second district, 5 in the first half of 2021, and the cumulative IF is as high as 48.571. It can be seen that the research and application potential of humidity-induced electrospinning technology is gradually emerging. The relevant literature is summarized as follows:

[1] Zz A , Hw B , Yang S , et al. Stretchable and resilient fibrous sponges tailored by interlocking double-network for warmth retention[J]. Composites Communications, 2021:100788. https://doi.org/10.1016/j.coco.2021.100788 (Q2, IF=4.915(3-year average, the same below))

[2] Hw A , Lei Z A , Yang S , et al. Ultralight and superelastic fibrous sponges with effective heat preservation and photo-thermal conversion for personal cold protection[J]. Composites Communications, 2021. https://doi.org/10.1016/j.coco.2021.100766 (Q2, IF=4.915)

[3] Wu H , Zhao L , Zhang S , et al. Ultralight and Mechanically Robust Fibrous Sponges Tailored by Semi-Interpenetrating Polymer Networks for Warmth Retention[J]. ACS Applied Materials & Interfaces, 2021. https://doi.org/10.1021/acsami.1c03658 (Q1, IF=8.437)

[4] Yf A , Dz B , Yh A , et al. Gradient structured micro/nanofibrous sponges with superior compressibility and stretchability for broadband sound absorption[J]. Journal of Colloid and Interface Science, 2021, 593:59-66. https://doi.org/10.1016/j.jcis.2021.03.013 (Q2, IF=6.314)

[5] Zhao L , Wu H , Jiao W , et al. Superelastic, lightweight, and flame-retardant 3D fibrous sponge fabricated by one-step electrospinning for heat retention[J]. Composites Communications, 2021:100681. https://doi.org/10.1016/j.coco.2021.100681 (Q2, IF=4.915)

[6] D Zong, L Cao, Y Li, et al.Interlocked Dual‐Network and Superelastic Electrospun Fibrous Sponges for Efficient Low‐Frequency Noise Absorption[J]. Small Structures, 2020. https://doi.org/10.1002/sstr.202000004 (New journal,refer to Small, Q1,IF=10.638)

[7]Leitao, Cao, Yang, et al. Ultralight and Resilient Electrospun Fiber Sponge with a Lamellar Corrugated Microstructure for Effective Low-Frequency Sound Absorption.[J]. ACS applied materials & interfaces, 2019, 11(38):35333-35342. https://doi.org/10.1021/acsami.9b12444 (Q1, IF=8.437)

The precise regulation of environmental temperature and humidity is the key to the success or failure of humidity-induced electrospinning experiments. Foshan Nanofiberlabs Co.,Ltd is a high-tech enterprises focusing on the electrospinning laboratory equipment, test equipment, production lines and research services , with independent R & D and production capacity, can provide a one-stop solution for electrospinning equipment and temperature and humidity control equipment. If you have relevant equipment needs, please contact us!