Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Abstract

Polycaprolactone(PCL) due to its good biocompatibility and biodegradability, is widely used in fracture fixation materials, surgical sutures, medical dressings, controlled drug release materials and tissue engineering scaffold materials. The research group of Professor Liu Yanbo from the School of Textile Science and Engineering of Wuhan Textile University explored the best process parameters for preparing PCL scaffoldsusing near-field direct-writingmelt electrospinning technology through orthogonal experiments. Based on the optimized process parameters, PCL scaffolds with different thicknesses, gaps and structures were prepared, and the corresponding hydrophilicity was characterized. The PCL scaffold is modified with chitosan (CS) and hyaluronic acid (HA) to improve biocompatibility and hydrophilicity. Fourier transform infrared spectroscopy (FTIR) analysis and antibacterial experiment results show that the adhesion of chitosan and hyaluronic acid on the surface of the PCL scaffoldhas a positive effect on the biocompatibility and antibacterial effect. Then use the PCL scaffold as a carrier for culturing cells .The modified PCL scaffold has good biocompatibility and porous structure andthe scaffold is conducive to cell adhesion and deep growth.

Introduction

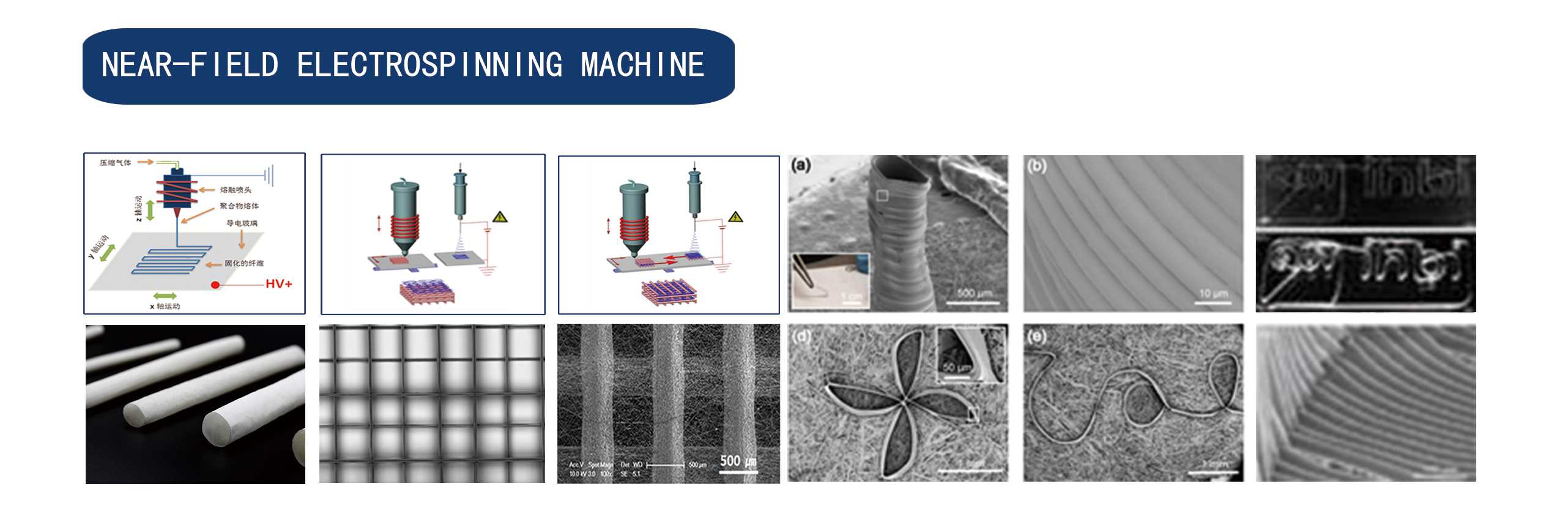

Different from near-field solution electrospinning (Electrohydrodynamics technology)), near-field direct writing melt electrospinning technology is an environmentally friendly and safe fiber forming method. This method has no solvent residue, and the spinning nozzle is not affected by ambient temperature and humidity. At the same time, the deposition position of the fiber can be accurately controlled, and the three-dimensional tissue engineering scaffold can be effectively prepared.

Results and Discussion

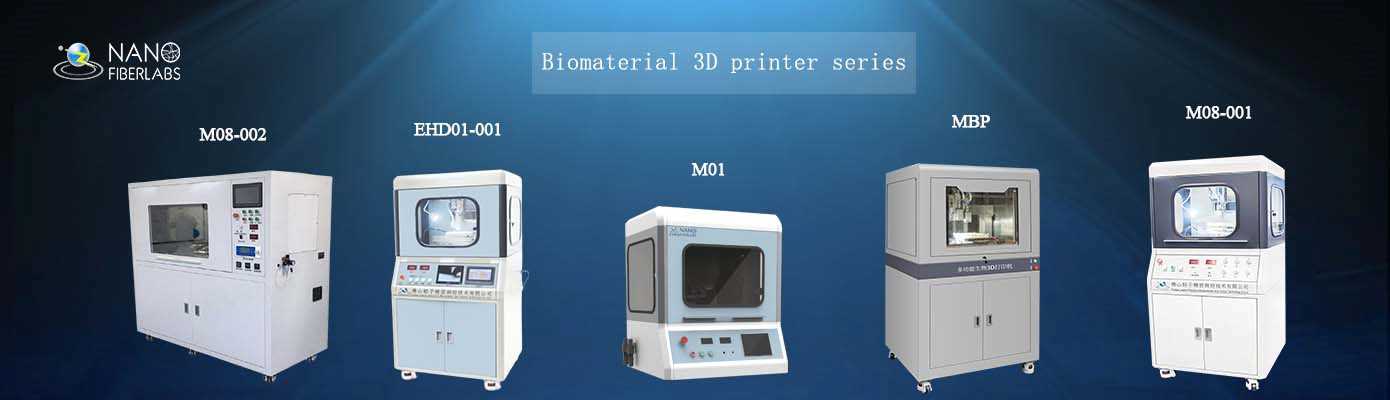

In this paper, PCL scaffolds with different structures,uniform fiber diameter, controllable size and orderly orientation were prepared by the near-field direct writing melt electrospinning technology. For the same structure, the thickness of the scaffoldsincreases as the number of layers increases. For the same structure, the thickness of the scaffolds increases as the number of layers increases. The thickness of the grid>the thickness of the two latitude and longitude circles>the thickness of the three latitude and longitude circles>the thickness of the trapezoidal structure (20 layers). The test analysis of PCL water contact angle shows that the thickness of the support has a certain influence on the contact angle. The thicker the thickness, the smaller the contact angle and the better the hydrophilic performance. Due to the large gap and large thickness of the PCL scaffolds, some droplets will penetrate, resulting in a small contact angle. The contact angle of the PCL scaffoldswith the same thickness, the same gap, and different structures does not change significantly.

By using chitosan and hyaluronic acid to modify the PCL scaffolds, the antibacterial, hydrophilic and biocompatibility of the PCL stent is effectively improved. The samples with inhibitory rate of Escherichia coli greater than 70% have antibacterial effect, and the rest have no antibacterial effect. The antibacterial rate of the PCL scaffold modified by chitosan solution at a concentration of 1% is 40.14%, less than 70%, which means unobvious antibacterial effect. The antibacterial rates of PCL scaffold modified with chitosan solution at concentrations of 2%, 3% and 4% are 75.48%, 77.75% and 78.78%, respectively, greater than 70 %, representing obvious antibacterial effect, but the difference in antibacterial effect among them is not very significant. This is because after the PCL scaffold is immersed in 2%, 3%, and 4% chitosan solutions, the chitosan on the surface of the PCL scaffold is basically saturated, and the increase in concentration has little effect on the antibacterial effect. However, in the case of 1% chitosan solution, there is less chitosan on the surface of the PCL scaffold. Therefore, it is believed that 2% of chitosan solution is more appropriate for the modification of the PCL scaffold.

Fig 1 Micrographs of ordered fibers prepared by Nanofiberlabs M08 equipment

Conclusions

In this subject, the PCL tissue engineering scaffolds with the fibers simulating the structure of natural extracellular matrix were prepared by NFDWMES technology. The PCL scaffolds optimal process parameters were the voltage of 4.5kV, the moving speed of 8mm/s, the melt temperature of 100°C, and the receiving distance of 0.7cm. The PCL scaffolds modified with chitosan solution have antibacterial properties, and the optimal mass fraction was 2%. Scanning electron microscopy images and Fourier transform infrared spectroscopy results verify the adhesion of chitosan gelatinous substances and hyaluronic acid on the fiber surface. After the PCL scaffold was modified with chitosan and hyaluronic acid, the contact angle is visibly reduced. The modified PCL scaffolds have good biocompatibility, and the porous structure of the scaffold is conducive to adhesion and deep growth of cells.

Article details:Characterizationon Modification and Biocompatibility of PCL Scaffold Prepared with Near-field Direct-writing Melt Electrospinning

CHEN Zhijun, HAO Ming, QIAN Xiaoming, CHEN Wenyang, ZENG Ming, HUANG Juan, LI Ruixin, FAN Jintu and LIU Yanbo* Chem. Res. Chinese Universities, 2021, 37(3), 578-583

DOI: 10.1007/s40242-021-1129-z

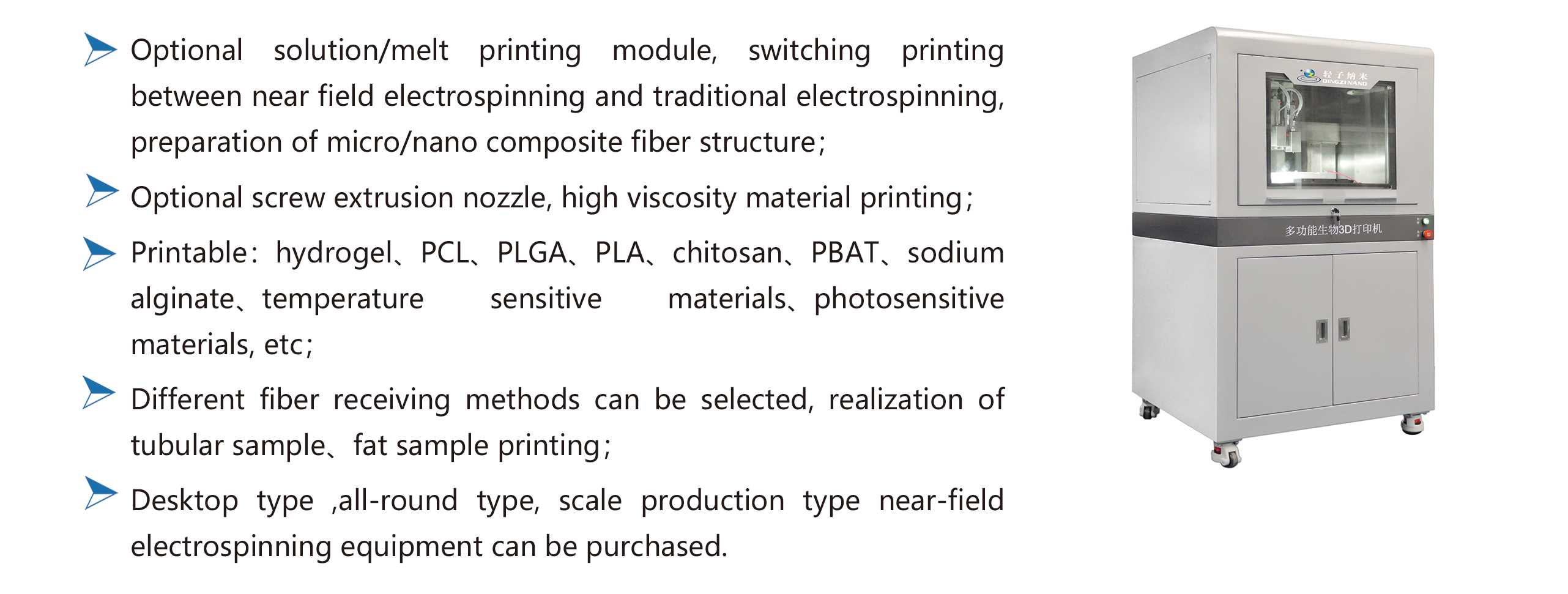

The near field direct writingelectrospinning (micro/nano 3D printing technology) can be divided into solution near-field electrospinning (EHD Electrohydrodynamics technology) and melt near-field electrospinning. It can produce micro nanostructures with small fiber diameter and orderly control. It is a hot research direction in Colleges and universities or research institutes in recent years. Foshan Nanofiberlabs Co , Ltd is a high-tech enterprises focusing on the electrospinning laboratory equipment, test equipment, production lines and research services with independent R & D and production capacity. We can provide a one-stop solution for electrospinning equipment and temperature and humidity control equipment. If you have relevant equipment needs, please contact us!