Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

catalogue:

▷ introduction

▷ wearable sensors for biophysical signals

▷ wearable energy storage device

▷ wearable energy collection device

▷ summary

Introduction:

According to IDC, the compound growth rate of the total global shipments of smart wearable devices from 2016 to 2020 was 44.5%. The global demand for smart wearable devices will continue to grow strongly in the next five years. However, designing intelligent wearable devices that can be seamlessly integrated with the human body is a difficult task. Electrospinning has emerged as a multifunctional platform, which can solve these challenges by manufacturing nanofibers with adjustable properties from polymer substrates.

APL bioengineering published by the American Physical Federation published a paper "recent progress in electrospun nanomaterials for wearables" on June 28. Professor Sameer sonkusale of Tufts University in the United States showed many advantages of electrospinning materials and summarized the new progress of Electrospinning in wearable electronic devices and systems. It is generally believed that wearable devices include micro electronic devices directly worn on human skin, which are used to sense various biophysical and biochemical signals or provide convenient human-machine interfaces (such as smart watches). Some key properties of wearable device materials are skin adaptability, breathability and biocompatibility. The ability to regulate the mechanical, electronic and chemical properties of materials is also important. Electrospinning, by using an electric field to produce nanofibers from polymer solutions, provides a universal platform for potentially addressing these challenges and assembling them into various forms, such as membranes, wires, or mats.

Wearable sensors for biophysical signals:

Nanofibers prepared by electrospinning have high porosity and high surface / volume ratio, and are a promising skin biosensor material. The porosity of nanofibers improves the permeability and permeability to gas and water vapor, making them an ideal matrix for skin interface, and functionalize them as sensors for different biophysical signals.

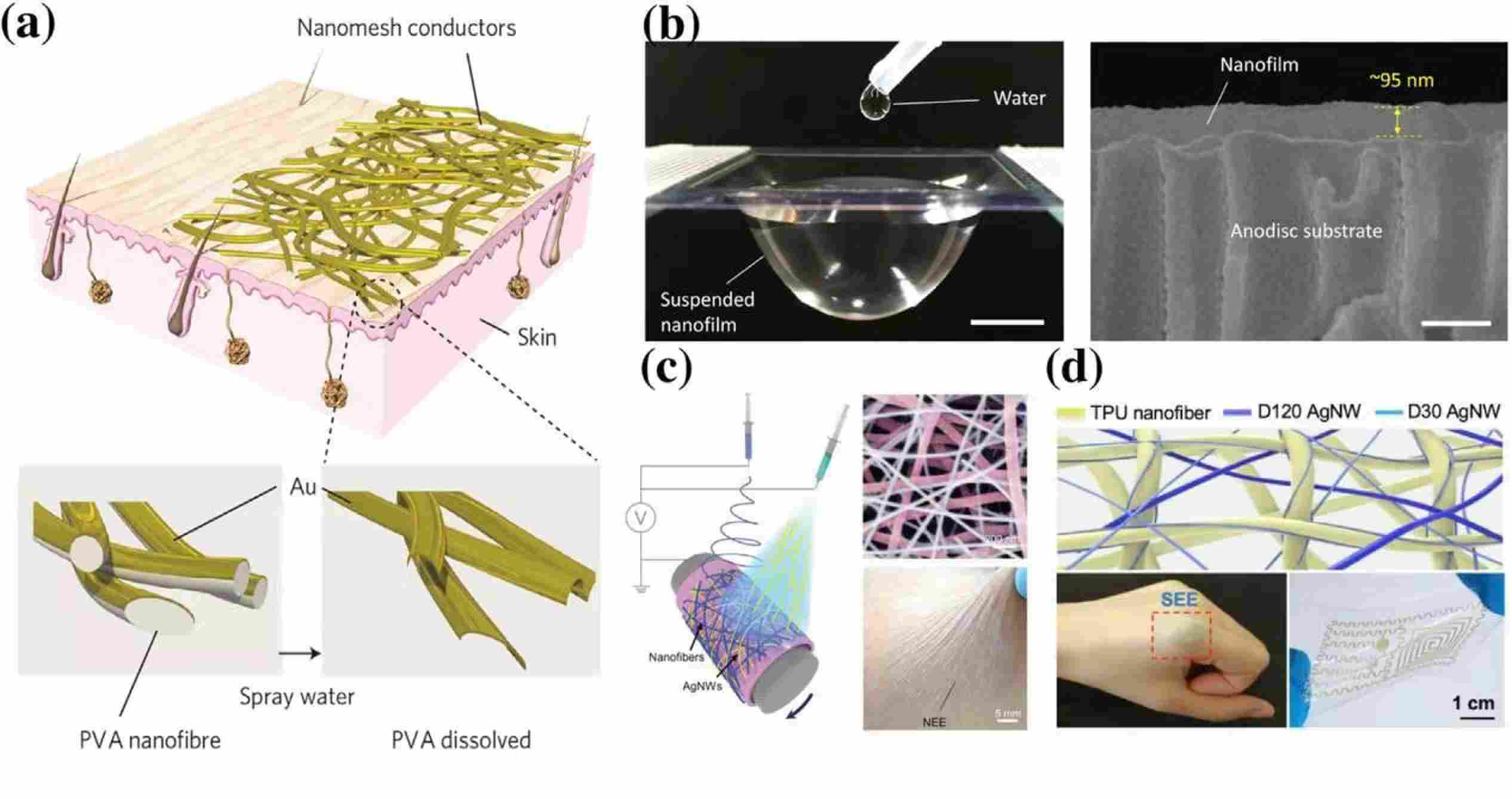

Monitoring biological potentials such as electrocardiogram (ECG) and electromyography (EMG) is the core of many wearable applications. Due to the ultra-low thickness, shape consistency and permeability, electrospun nanofibers are more promising as skin electrodes for biopotential monitoring. The porosity of nanofibers improves surface contact and increases adhesion. In addition, it makes nanomesh electrodes breathable, which is a key attribute of any device placed on the skin for a long time. These ultra-thin films, usually called nanomesh conductors, can be electrically connected to human skin through epidermal electrodes to transmit biopotential signals. These nanomesh sensors consist of flexible breathable substrates used to attach them to the skin and are covered with a conductive coating on top.

Another kind of wearable devices characterized by stretchable conductive varistors are widely used in motion, strain and pressure sensing. High porosity and large surface volume ratio make electrospun nanofibers easily absorb volatile materials and provide rapid response through color changes or electrical signals. It can be used as a wearable gas sensor to measure body metabolism.

Wearable energy storage device:

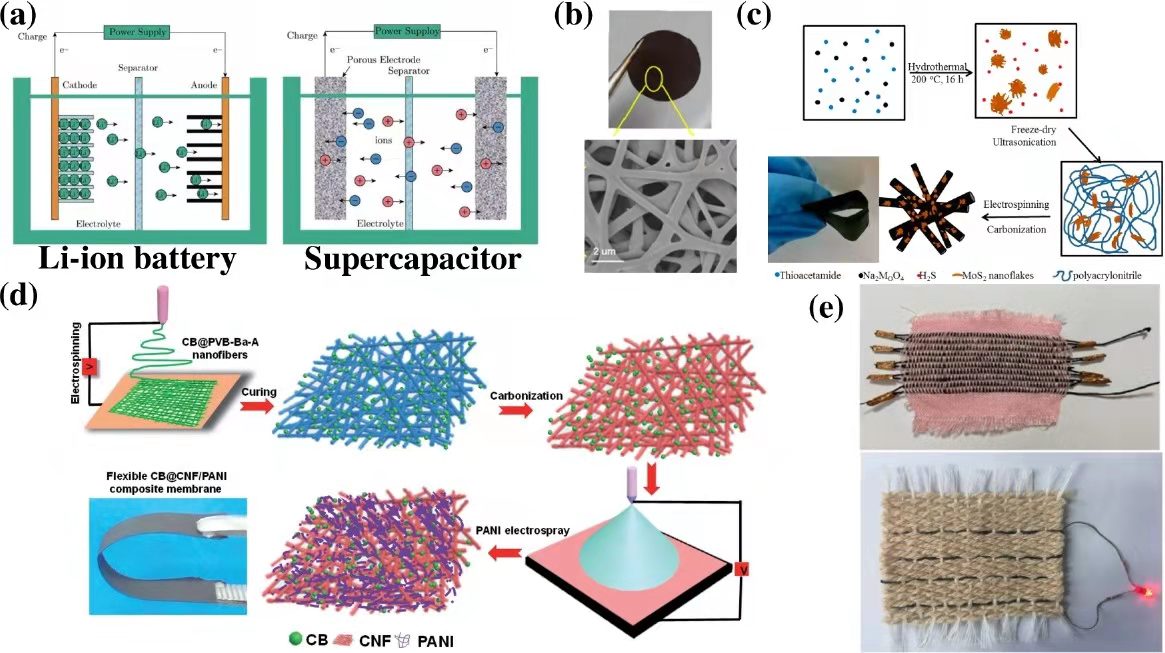

The basic building blocks of the wearable platform, such as batteries, supercapacitors, silicon rectifier antennas, photovoltaic cells and transistors, can be achieved by using electrospun nanofibers. Porous nanofibers from electrostatic nanoparticles and composites have improved lithium storage capacity, charge and discharge kinetics, cycle stability and electrochemical properties. Despite the exponential growth of communication systems and sensing platforms in recent years and the continuous progress of technology, battery life is still one of the biggest design challenges in today's wearable technology. Lithium ion batteries are mainly used in wearable devices because they are safe to operate, light in weight, small in size, high in charging capacity, and require less maintenance [figure 2 (a)]. Therefore, it is an excellent candidate material for manufacturing high-efficiency, flexible and stretchable batteries.

Some scholars have developed fused electrospun carbon fiber felt as a high-performance anode material in lithium-ion batteries to improve the specific capacity and electrochemical conductivity of carbon nanofibers, simplify the manufacturing process and further improve the battery charging capacity [figure 2 (b)]. In another study, researchers demonstrated the use of nitrogen-based polymer precursors in the manufacture of high-performance porous cathodes. Various other anode materials in lithium-ion batteries that have been synthesized and manufactured include ultrafine SnOx particles, silicon core /c-shell silicon nanowires, and highly graphitized carbon nanofibers. Electrospun carbon nanofibers with embedded inorganic materials have been shown to provide electrochemical improvements in lithium-ion batteries. Electrospinning is helpful to embed nano sheets / nano plates of functional materials into the structure of conductive nanofibers to prepare battery materials with unique structures. These composite structures not only provide the regulation of rate performance, but also prove the extreme limitation of reaction in these flexible ultra-thin nanostructures to improve battery performance.

Wearable energy collection device:

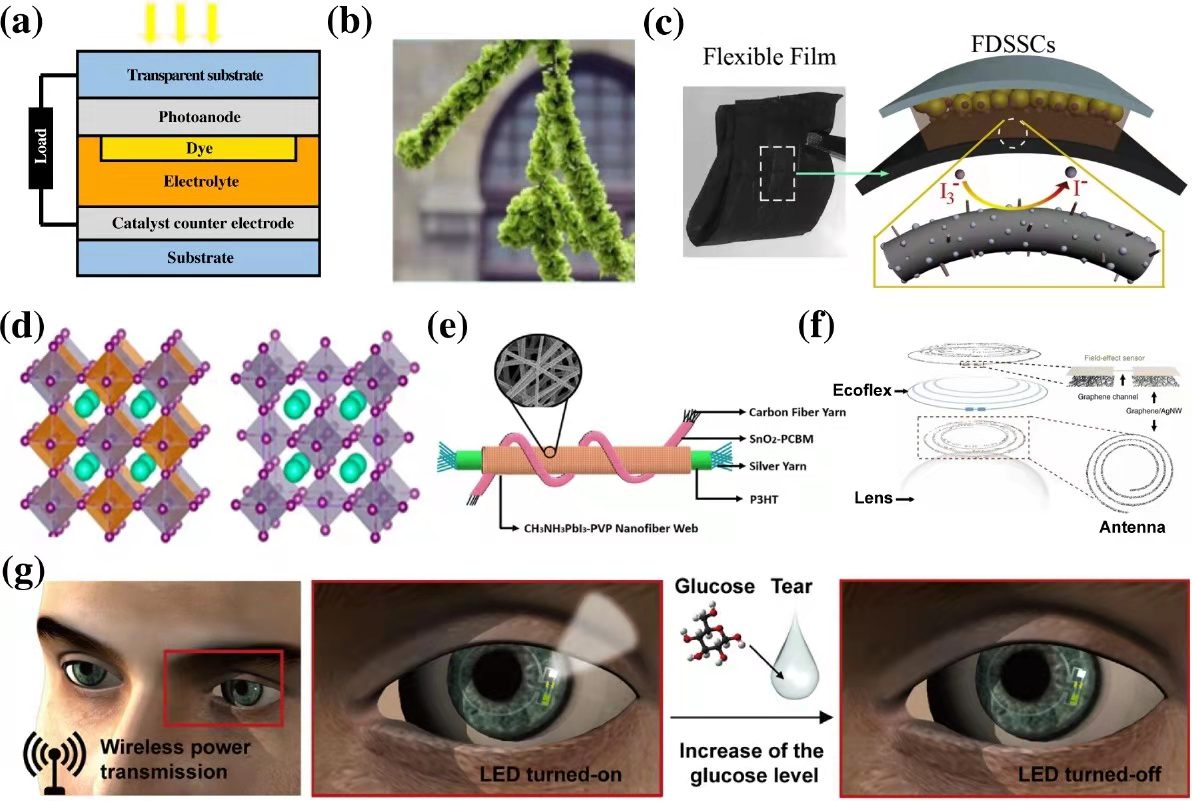

With the rapid development of the Internet of things, flexible solar cells have become a promising candidate for wearable power. Electrospun nanofibers are suitable for wearable power supply because of their low-cost, easy to manufacture and adjustable physical and chemical properties. Several examples of the introduction of dye-sensitized solar cells (DSSC) into electrospun nanofibers as components have demonstrated improved efficiency in wearable applications. In one study, a layer of electrospun nanofibers was used to absorb the liquid electrolyte leakage of DSSC. The nanofibers can accommodate a large number of electrolytes, significantly reducing the rate of electrolyte leakage or evaporation.

Electrospun nanofibers provide cheap and effective substitutes for other electrolyte technologies, such as gel electrolytes or electrolytes doped with precious metal particles. The interconnection structure of nanofibers enables them to maintain the mobility of charge carriers, making them have semiconductor like characteristics, which helps to transfer electrons and holes to the electrode before recombination.

summary:

In the latest research, they showed many advantages of electrospinning materials. Since the emergence of electrospinning, significant progress has been made in applying this technology to a variety of applications, especially in the field of wearable device electronics. Looking forward to the future, broadening the range of material selection and improving the convenience of integration with human physiology are the key aspects of the development of electrospun equipment. The new strategy of providing seamless integration of wearable devices with power and communication components is the key to improve the overall function of any wearable system, which needs further research, especially in electrospinning devices. The author believes that in the next few years, electrospinning technology will become a key technology of multi-functional, feasible and cheap wearable device manufacturing.

DOI:doi.org/10.1063/5.0088136