Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Introduction:The spiral arrangement in cardiac muscle tissue is very important to achieve physiological pumping efficiency. However, it is difficult to test this possibility, because it is challenging to reproduce the fine spatial characteristics and complex structure of cardiac muscle tissue using current technologies. Recently, a paper published in science studied focused rotary jet spinning (frjs), which is an additive manufacturing method that can quickly manufacture micron and nanofiber scaffolds with programmable three-dimensional geometric arrangement.

In order to study the effect of spiral muscle arrangement on cardiac function, previous studies used controlled arrangement and three-dimensional (3D) geometry to reconstruct the multi-scale structure of the heart. 3D extrusion printing has been proved to be of significance in reconstructing these complex structures. Fiber spinning technology can replicate these fine spatial features with higher processing capacity, so scholars provide a potential solution, and it has been used in engineering tissue scaffolds, such as heart valves and ventricular models. However, this method usually cannot control 3D geometry while maintaining controllable arrangement.

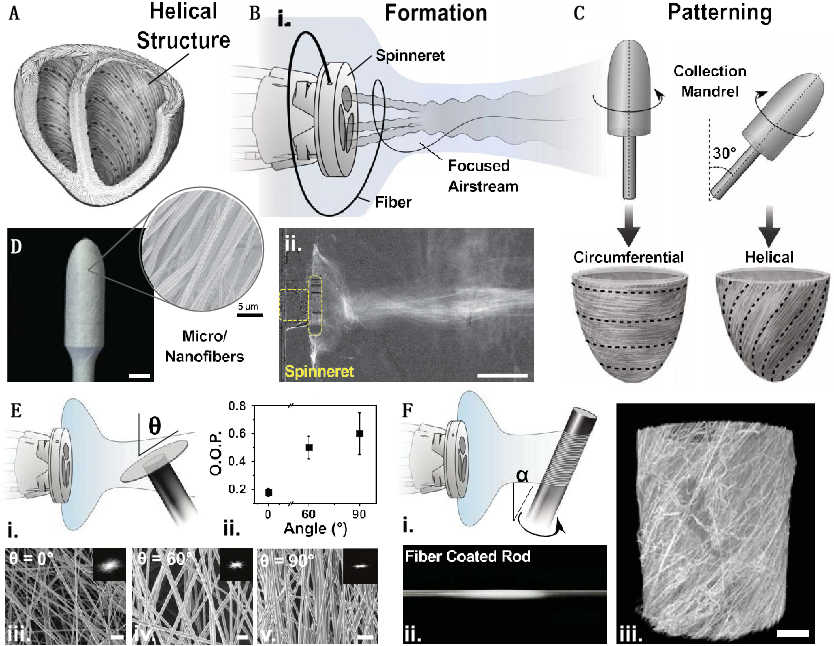

Therefore, the author developed focused rotary jet spinning (frjs), which is an additive manufacturing method. Centrifugal jet spinning can quickly form polymer micro and nano fibers, and then focus and spatial pattern through controlled air flow. This method allows rapid fabrication of fiber structures with 3D programmable fiber arrays. Because fibers can be used to guide tissue formation, complex anatomical structures can be reconstructed.

Fig. 1 focused rotary jet spinning for producing spiral structure. (A) Schematic diagram of spiral arrangement of human heart (B and C) frjs uses concentrated air to divide fiber manufacturing into forming (B, I) and patterning (c) stages, allowing control of alignment (B, II) different contrast projections of fiber flow (maximum projection; scale, 5 cm) (d) image of polycaprolactone spun on mandrel (scale, 5 mm), with corresponding scanning electron microscope (SEM) image, Show aligned micron and nanofiber formation (average fiber diameter, ~900 nm; scale bar, 5 mm) (E) show the schematic diagram that the collection angle (q) determines the fiber deposition arrangement (I), OOP represents the relative average arrangement (error bar, average SD) (II) SEM micrographs (III to V; 0 °, 60 ° and 90 °), and insert the corresponding 2D Fourier transform, Indicates the degree of alignment based on the collection angle (scale bar, 5 mm) (f) shows the schematic diagram of HA fiber manufacturing based on the angle (I), a, reconstruction micro computed tomography of representative fiber coated rods (II) and HA scaffolds (III scale bar, 200 mm)

Focusing the fibers in this way enables them to deposit conformally, and the fibers will adhere well to convex structures or features whose radius of curvature exceeds the focal spot size. This method can be used for various material components, such as nylon, polyurethane and gelatin, while maintaining a single micron fiber diameter.

Since micro and nano fibers can simulate the structural characteristics of ECM proteins, the authors studied how frjs can be used to control the anisotropic distribution of fiber arrangement. This ability to control fiber orientation shows that more complex patterning can be achieved by moving the target relative to the air flow. In order to test whether frjs can reproduce the key geometric features of the heart, such as the spiral arrangement and layered tissue structure identified in the rodent model, fibers are collected on an inclined rotating cylinder to produce a spiral arrangement (Fig. 1F), and are collected on an incrementally rotating disk to produce multilayer fiber sheets. These data show that frjs can be used to form a 3D contractile heart model.

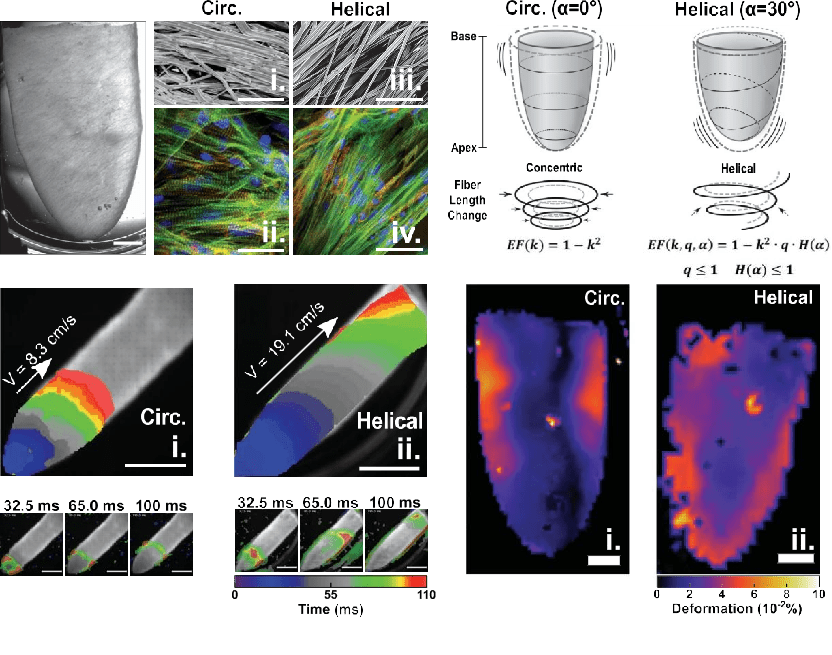

Figure 2 controlled spiral arrangement of tissue scaffolds. (A) Bright field micrograph of HA ventricular model (gelatin fibers inoculated with nrvms; scale, 2 mm) (b) SEM micrograph fibers from CA [(I), a = 0] and ha [(III), a = 45] cylinders, with corresponding myocardial cell immunofluorescence staining (two and four) [nrvm; blue, DAPI (4 ', 6-diamidino-2-phenylindole); green, F-actin; red, sarcomere], The display fiber helps guide tissue alignment (scale bar, 50 mm) vitamin CIRC, and the isochron (top) of the circumference (c) with the corresponding rest frame (bottom), indicating calcium transients along the extended ventricular surface, shows the increased shear wave propagation of the HA scaffold. Tissue point stimulation apex [(I), CA; (II), HA] (scale bar, 5 mm). (D) Schematic diagram of Ca (left) and ha (right) ventricles, illustrating the difference in ventricular wall displacement during contraction. CA contracts into concentric rings, while ha follows torsional motion, resulting in different predicted EFS [k, strain, Q, apical shortening, H (a), radial shortening] (E) deformation map generated by Ca (left) and ha (right) ventricular models during contraction (scale, 2 mm)

In order to prove the ability of frjs to realize hierarchical biological manufacturing, a full-scale model of human heart muscle tissue was constructed. This model is assembled from independent parts. Microns and nanofibers are plated on a soluble collector in the shape of four chambers of the heart. Through our method based on microns and nanofibers, these local structures can be retained in the whole tissue volume, thus allowing hierarchical assembly of the tissue. These key features indicate that fiber-based manufacturing is a promising method to realize the whole organ biological manufacturing, which can be used to replace or combine with emerging biological manufacturing platforms, such as 3D extrusion printing. In general, these observations show that frjs can quickly manufacture fiber scaffolds that span multiple length scales and can adapt to different geometric shapes.

In addition to biological manufacturing, frjs can also play an important role in other additive manufacturing applications, because it provides productivity equivalent to current industrial processes, while achieving micron and nano scale feature sizes and controlled 3D alignment. The high surface area volume ratio of microns and nanofibers makes them ideal candidates for controlled absorption and release of chemicals. This shows that frjs may be an important technology in the industrial manufacturing process. These industrial manufacturing processes adopt the principle of hierarchical design, and need to control several orders of magnitude of space.

DOI: 10.1126/science. abl6395