Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Introduction: in the field of sensors, the stable and durable flexible and stretchable conductor is still a great challenge that restricts its development. Electrospun nanofibers with high surface area to volume ratio can be used to develop sensors with higher load capacity, better sensitivity and faster response time. This paper has collected five articles about the latest progress of sensors from June to July for everyone to study.

Xujianhong team, State Key Laboratory of chemical engineering, Department of chemical engineering, Tsinghua University ACS Nano: two-dimensional hybrid nano chip supercapacitor: from building block structure, fiber assembly and fabric structure to wearable applications

▷ fiber based supercapacitors (F-SCs) have attracted extensive interest in the fields of wearable technology, energy and carbon neutralization due to their high deformation flexibility, fast charging and discharging ability, long-term stability and energy saving ability.

▷ in this paper, the latest progress in the manufacture of F-SCs fiber electrodes is summarized. Various basic principles of 2D hybrid nanosheets in surface control, pseudo capacitance modification and microstructure operation are introduced to promote rapid electron transfer and charge conduction, and various spinning methods for assembling and manufacturing complex fibers with advanced nano / microstructure, including layered skeleton, anisotropic backbone, surface / entire porous framework and vertical arrangement network, to promote ion dynamics transmission / storage.

▷ so far, various materials have been developed to produce nanofibers by electrospinning, such as organic material polymers, chain entangled small molecules and sol gel composites. Materials that meet the requirements of different fields and dimensions, including 0d nanoparticles / nanodots, 1D nanotubes / nanowires and 2D nanosheets, have been introduced into organic polymers to prepare multifunctional nanofibers.

▷ this paper emphasizes the high flexibility / strength, superior conductivity and stable operation of multifunctional fabrics, which realize high energy density, deformability and robust stability under harsh conditions, especially potential power supply applications, including flexible electronic equipment, self powered function and energy sensor system.

DOI:doi.org/10.1021/acsnano.2c02841

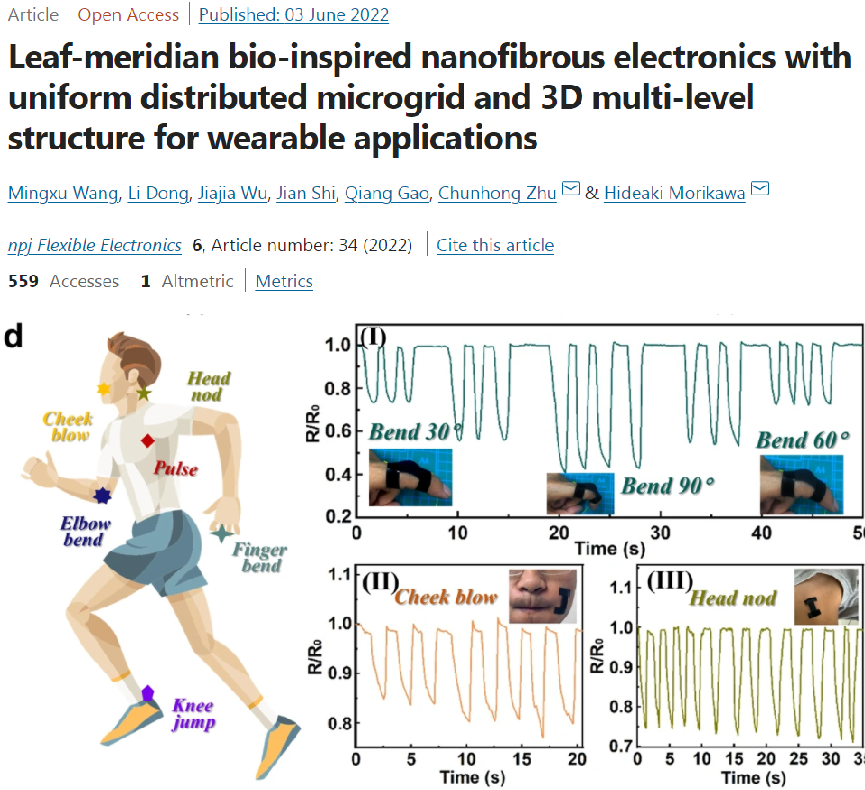

2. The npj flexible electronic:leaf meridian bionic nanofiber electronic products of Hideaki Morikawa team in the Graduate School of medical science and technology, Takeshi University, Nagano, Japan, have evenly distributed micro grids and 3D multilayer structures, which can be used in wearable applications

▷ the interface between the active electron and its contact target determines the sensing response of the high-sensitivity sensor. However, due to the limitation of surface engineering strategy, it is difficult to adjust and maintain the interface characteristics.

▷ inspired by the leaves of nature, this study prepared a spatial multilayer nanofiber film with uniformly distributed grid like microstructure, in which carboxylated carbon nanotubes / poly (3,4-ethylenedioxythiophene) (PEDOT) were modified to the surface of grid like polyurethane (PU) nanofibers through the combination of metal mesh templates, and treated with in-situ polymerization and ultrasound.

▷ electrospun nanofibers provide an attractive platform for us because of their advantages and characteristics in flexibility, high specific surface area and a variety of fiber morphology. Feasible nanofiber components have remarkable attraction and advantages in designing and manufacturing thin, soft, light, breathable and comfortable electronic devices. Therefore, sensors based on nanofibers have been widely studied as building blocks of flexible electronic devices.

▷ in addition, as a scalable and integrated platform, researchers also demonstrated its multifunctional applications in electrothermal conversion and energy collection. All these results show that nanofiber membranes may be used in the next generation of wearable devices.

DOI:doi.org/10.1038/s41528-022-00171-x

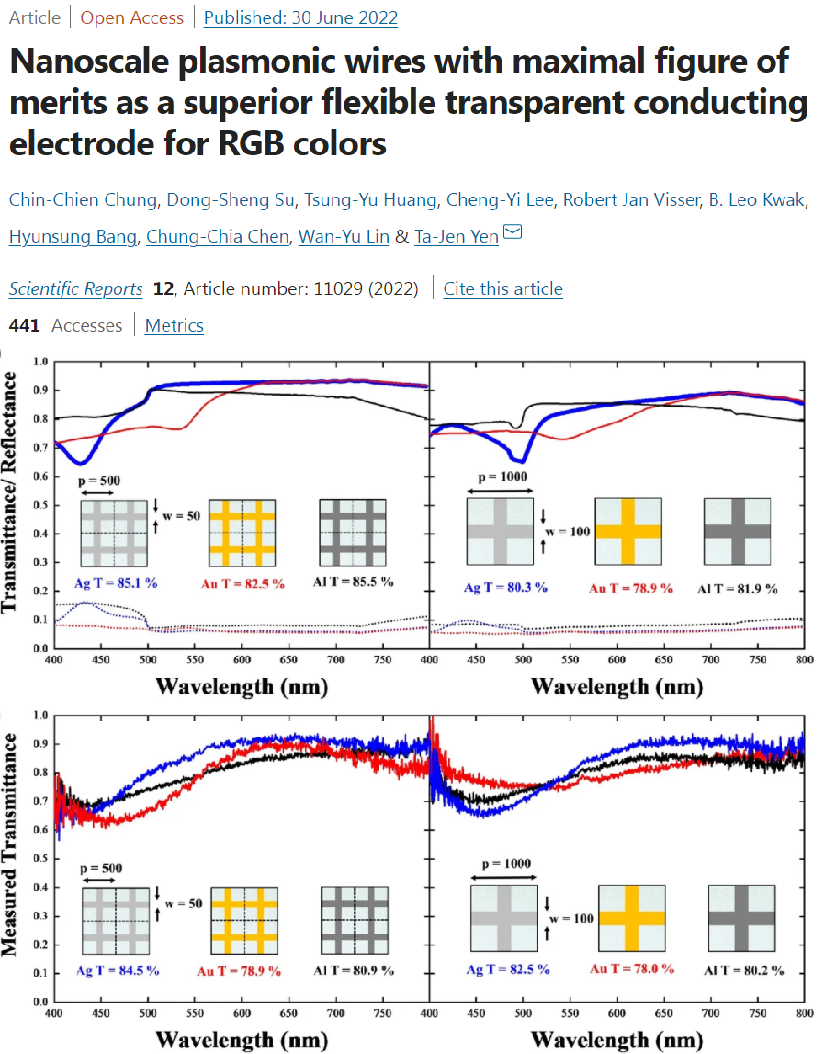

3. Scientific reports of TA Jen yen team of National Tsinghua University: nano plasmon wires with the highest value of excellence are used as high-quality flexible transparent conductive electrodes with RGB color

▷ with the increasing application in modern optoelectronic devices, the demand for high-quality conductive transparent electrode (TCE) candidate materials has become significant and urgent. However, increasing both transmittance and conductivity is an inherent limitation.

▷ the most advanced micron level metal structure achieves 90% transmittance and 10 Ω /sq sheet resistance in the electrospinning process, and 88.6% transmittance and 2.1 Ω /sq40 sheet resistance in the lithography process. These two kinds of metal wires are then integrated into solar cells and oled42 applications. However, once the pixel size of OLED display is close to the sub micron level, these two technologies will have serious deficiencies.

▷ in this work, we propose silver nanoscale plasma wire (Ag NPW), which acts as TCE in the visible region by reducing its corresponding plasma frequency. By carefully designing the geometric size of silver NPW, we also optimized the performance of red, green and blue respectively.

▷ obviously, our silver NPW provides a larger fom than the traditional TCE usually composed of indium tin oxide, and shows further advantages of flexibility and less moire effect in the application of flexible and high-resolution optoelectronic devices.

DOI:doi.org/10.1038/s41598-022-14756-z

4. Professor Kong lingbing's team from Shenzhen University of science and technology: synthesis and modification of flexible mxene based composite film and its application as supercapacitor electrode

▷ mxenes is a kind of two-dimensional planar nano materials. Due to its large specific surface area, high ductility, high conductivity, strong hydrophilic surface and high mechanical flexibility, it has been widely explored in the development of various functional materials with expected properties.

▷ this paper reviews the latest progress in the synthesis, modification and application of mxene based composite films as electrode materials for flexible energy storage devices. In the synthesis of mxenes, the development and exploration of etchants are mainly introduced.

▷ and various film-forming processes, such as rolling, vacuum filtration, rotary casting, spraying, electrophoretic deposition, electrospinning, inkjet printing and mechanical pressing, have been used to make mxene films.

▷ in addition, in order to develop mxene based composite films, the components used to modify mxene nano sheets, including 0d, 1D and 2D nano materials, are summarized, and the research directions of such materials are discussed, such as energy storage (such as supercapacitors and batteries), electrocatalysis, water purification, biomedicine, electromagnetic absorption / shielding materials, sensors, etc.

DOI:doi.org/10.1002/smll.202201290

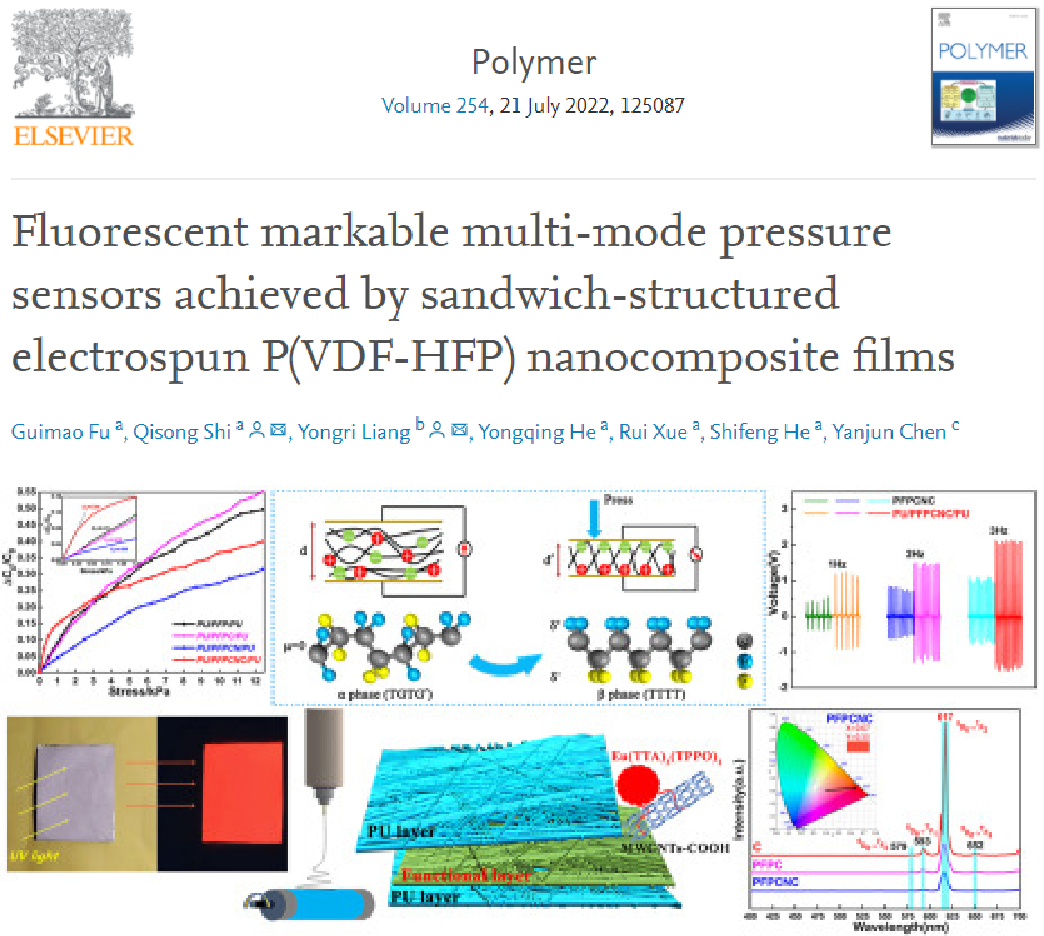

5. Professor Shi Qisong's team from Beijing Institute of petroleum and Chemical Technology: using sandwich structure electrospun P (VDF-HFP) nanocomposite film to realize fluorescence labeled multimode pressure sensor

▷ the development of multifunctional piezoelectric polymer films is of great significance for many application fields, such as wearable functional devices, flexible sensors and actuators.

▷ in this study, multilayer P (VDF-HFP) nanocomposite films were prepared by electrospinning technology, and multi walled carbon nanotubes COOH and europium complexes were used as fillers to realize fluorescence labeled multimode pressure sensors.

▷ sandwich structure devices are prepared using electrospun polyurethane (PU) nanofiber membrane and P (VDF-HFP) composite nanofiber membrane, in which p (VDF-HFP) composite nanofiber membrane is used as the core electroactive layer, and Pu nanofiber membrane is used as the skin layer. The sandwich structure device has high sensitivity, high voltage output (2.1V), fluorescence function, good flexibility and good thermal performance at ultra-low voltage (<1 kPa).

▷ the results show that sandwich structure devices based on fluorescent labeled electroactive P (VDF-HFP) composite nanofiber film have great application potential in the field of multifunctional flexible sensors and intelligent wearable devices.

DOI:doi.org/10.1016/j.polymer.2022.125087